Home > Product > Gas turbine system > GE DS3800DFXD1B1B Gas turbine serial card

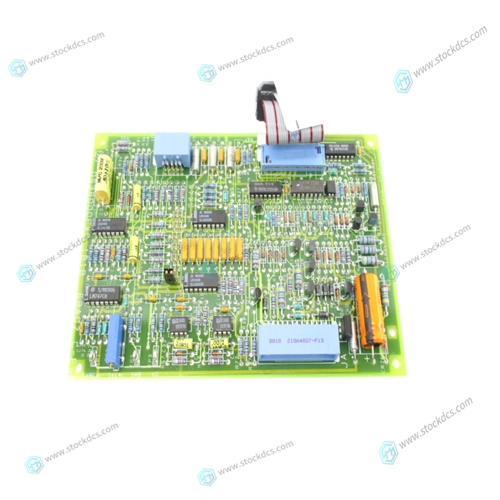

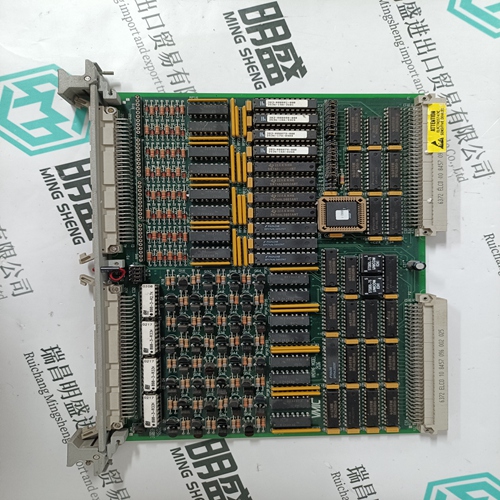

GE DS3800DFXD1B1B Gas turbine serial card

- Product ID: DS3800DFXD1B1B

- Brand: GE

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:GEDS3800DFXD1B1BGas turbine serial card

- Get the latest price:Click to consult

GE DS3800DFXD1B1B Gas turbine serial card

• The YASNAC XRC has a fully sealed construction, designed to keep external air containing oil mist out of the XRC. Be sure to keep the XRC doors fully closed at all times, even when the controller is not operating. • Open or close the two locks in each door with the minus driver when opening or closing the doors for maintenance after the main power is turned off. (CW:Open, CCW:Close) Make sure push the door closed and turn the door lock with the driver. When the door is closed, turn the door lock until the door clicks.

• Open the door and check that the seal around the door is undamaged.

• Check that the inside of the XRC is not excessively dirty. If it is dirty, determine the cause, take measures to correct the problem and immediately clean up the dirt.

• Fully close each door lock and check that no excessive gaps exist around the edge of the door.

Cooling Fan Inspections

Inspect the cooling fans as required. A defective fan can cause the XRC to malfunction because of excessive high temperatures inside. The servo ascending fan and backside duct fan normally operate while the power is turned ON. Check if the fans are operating correctly by visual inspection and by feeling air moving into the air inlet and from the outlet.When the message of the "Cooling fan in control box stopped" is displayed, it may be caused by the error occurrance at the cooling fan (JZNC-XZU02) on the CPU rack . The playback operation (execution of the JOB) is not performed when the error is occurred at the cooling fan. In this case, the alarm 4119 "FAN ERROR (IN CONTROL BOX)" is appeared by 72 hours later. The messege of the "Cooling fan in control box stopped" is displayed, carry out an inspection and the replacement of the cooling fan on the CPU rack as soon as possible.

Emergency Stop Button Inspections

The emergency stop buttons are located on both the playback panel and the programming pendant. Confirm the servo power is off by pressing the emergency stop button on the playback panel after the servo ON button, before the robot is operated.The programing pendant is equipped with a three-position deadman switch. Perform the following operation to confirm the deadman switch operates.

Press [TEACH] on the playback panel to switch to teach mode. The [TEACH] lamp lights. 2. Press [SERVO ON READY] on the playback panel. The [SERVO ON READY] lamp blinks.

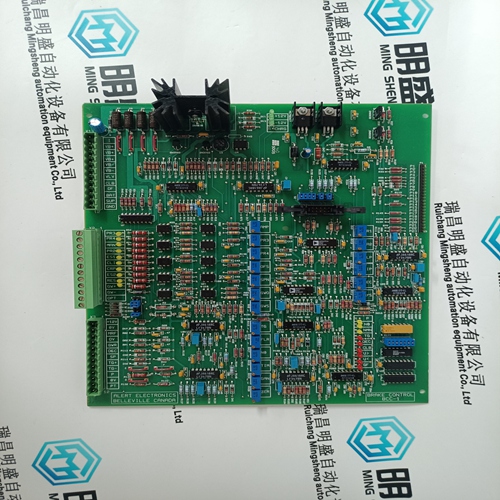

[Main Products]

Main products: PLC and DCS system spare parts modules of world famous brands

①Allen-Bradley 1756、1746、1747、1771、1785

②Schneider 140 Series PLC module

③General electric GE IC693 IC697 IC698 Series PLC module

DS200 DS3800 DS215 IS200 IS215 IS220 Series gas turbine module

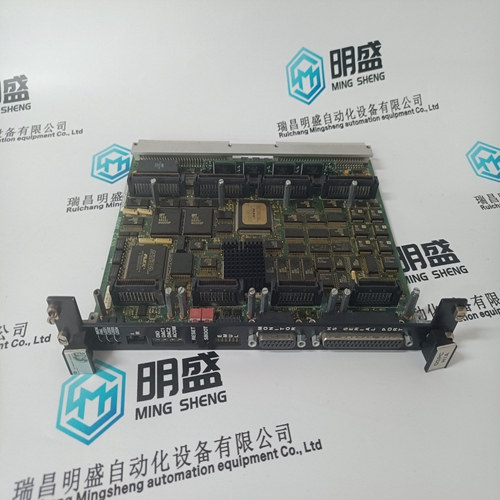

VMIVME Control module of series

④Bently:3500 series cards 3500/22M、3500/15、3500/92 And other products

⑤ICS TRIPLEX

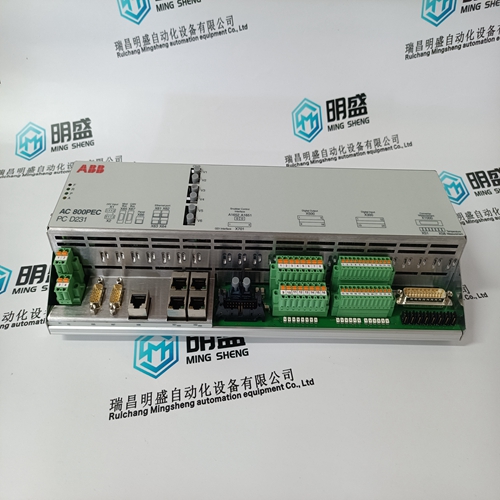

⑥ABB Robots. FANUC Robots、YASKAWA Robots、KUKA Robots、Mitsubishi Robots、OTC Robots、Panasonic Robots、MOTOMAN Robots。

⑦EMERSON:Spare parts for OVATION system, WDPF system and MAX1000 system.

⑧ Invensys Foxboro: I/A Series system, FBM (field input/output module) sequential control, ladder logic control, accident recall processing, digital analog conversion, input/output signal processing, data communication and processing, etc. Invensys Triconex: redundant fault-tolerant control system, Zui modern fault-tolerant controller based on triple module redundancy (TMR) structure.

⑨Woodward:505 series governor 9907-164 And other products

⑩Bosch Rexroth:Indramat,I/O module,PLC CPU,Motors, drives and other products.

◆Motorola:MVME 162、MVME 167、MVME1772、MVME177and other products.