Home > Product > Gas turbine system > GE DS200TCRAG2A Interface card

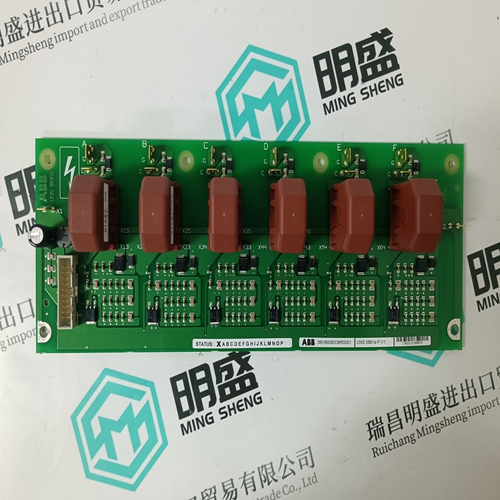

GE DS200TCRAG2A Interface card

- Product ID: DS200TCRAG2A

- Brand: GE

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:GEDS200TCRAG2AInterface card

- Get the latest price:Click to consult

GE DS200TCRAG2A Interface card

At the job CALL, RET, END instruction, when operating the job call stack, internal control data of inside was abnomal. • Reset the alarm. Select the job again and repeat the operation. • If the error occurs again, contact your YASKAWA representative. 4444 UNSUCCESSFUL FINE POSITIONING [Binary Data]

• When executing PL=0 or interrupting external servo, the servo deflection was not put within time.

• Excessive external force

• The servopack, the motor were abnormal.

• Reset the alarm. In case an external force is affecting the robot, move the robot to remove the external force and repeat the operation.

• In case the phenomenon occurs again without any external force, try to insert the XCP01 circuit board again.

• If the error occurs again, contact your YASKAWA representative.

When the interpretation process section

of job annuled the content of interpretation and started to interpret again, various kinds of data were attempted to be initialized. At the time,a disagreement of data occured. • Reset the alarm. Select the job and repeat the operation. • If the error occurs again, contact your YASKAWA representative. 4446 OVER VARIABLE LIMIT [Decimal Data] The range of the numerical value of the variable for storage destination was exceeded. Increase the variable range at the storage destination or rewrite the job to bring the number of variables in range. 4447 DEFECTIVE TAUGHT POINT (CIRC) A straight line linked the three points. Reset the alarm and teach again

When executing the weaving motion control

the control error occurred in the path operation process. Data stands for the alarm factor. 4:Weaving speed instruction was moving time instruction, moving time was less than 0. 5:Weaving speed instruction was frequency instruction, frequency was less than 0. 6.Weaving stopping time was negative 7:Vertical direction distance at or horizontal direction distance was 0 in triangular wave, L type weaving. 9:Distance between P point and control point was less than 0 in the wrist weaving Except above:Control error • 4:Set 0.1 seconds or more in the moving time of weaving file. • 5:Set 0.1 hertz or more in the frequency of weaving file. • 6:Set a positive value in the stopping time of weaving file. • 7:Set 1mm or more in the vertical direc tion, horizontal direction distance of weaving file. • If the error occurs again, contact your YASKAWA representative

[Main Products]

Main products: PLC and DCS system spare parts modules of world famous brands

①Allen-Bradley 1756、1746、1747、1771、1785

②Schneider 140 Series PLC module

③General electric GE IC693 IC697 IC698 Series PLC module

DS200 DS3800 DS215 IS200 IS215 IS220 Series gas turbine module

VMIVME Control module of series

④Bently:3500 series cards 3500/22M、3500/15、3500/92 And other products

⑤ICS TRIPLEX

⑥ABB Robots. FANUC Robots、YASKAWA Robots、KUKA Robots、Mitsubishi Robots、OTC Robots、Panasonic Robots、MOTOMAN Robots。

⑦EMERSON:Spare parts for OVATION system, WDPF system and MAX1000 system.

⑧ Invensys Foxboro: I/A Series system, FBM (field input/output module) sequential control, ladder logic control, accident recall processing, digital analog conversion, input/output signal processing, data communication and processing, etc. Invensys Triconex: redundant fault-tolerant control system, Zui modern fault-tolerant controller based on triple module redundancy (TMR) structure.

⑨Woodward:505 series governor 9907-164 And other products

⑩Bosch Rexroth:Indramat,I/O module,PLC CPU,Motors, drives and other products.

◆Motorola:MVME 162、MVME 167、MVME1772、MVME177and other products.