Home > Product > Gas turbine system > GE DS200TCCAG2A Gas turbine card

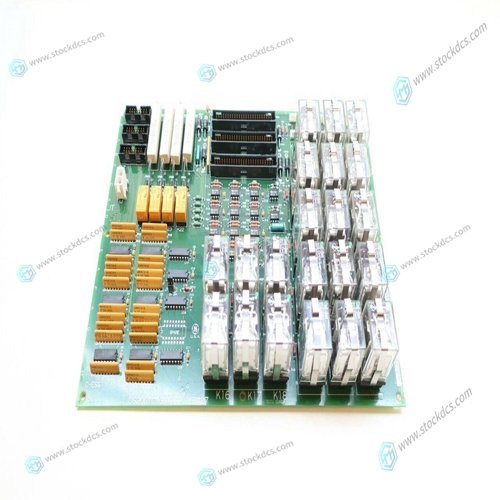

GE DS200TCCAG2A Gas turbine card

- Product ID: DS200TCCAG2A

- Brand: GE

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:GEDS200TCCAG2AGas turbine card

- Get the latest price:Click to consult

GE DS200TCCAG2A Gas turbine card

Metal parts in the switching cabinet must be connected with each other having large areas of contact and must carry high frequencies very well. Avoid anodized, yellow-passivating and painted surfaces which can have very high resistance values based on the frequency! Make sure that the metals lie close together in the chemical electromotive series! Use the good conductivity and the large surface of the galvanized mounting plate as earth potential! Relays, contactors and solenoid values built into the same circuit must be connected with spark-suppressing components limiting over voltage spikes. This applies also if these parts are not mounted in the same cabinet as the servo regulator.

The shield for the analog signal lines

must be installed on one end and, if possible, in the switching cabinet. Ensure a connection which provides extensive contact and which is low - resistant! The shield for the digital signal lines must be installed on both ends, must have extensive contact and must be low resistance. An additional equalizer is to be laid parallel when there are potential differences. It is necessary to use plugs with metal enclosures with separable connections. 6. Avoid unnecessary extra loops on all connecting cables. All measures regarding filtering and shielding can be short cicuited on them with high frequency. Connect unused wires in cables on both ends to the equipment ground conductor.

Unshielded cables of a cicuit

the conductors going out and returning, should be twisted due to symmetrical interferences. 8. Separate physically "live" and "dead" wires even in the planning phase. Give special attention to the motor cables. The area of the common terminal strip-line input and motor output is especially endangered. 9. Relays, contactors and solenoid values. The cables should be laid in the switching cabinet as close as possible to the ground; wires hanging freely in the air are preferred EMC victims as well as active and passive aerials. 10. When operating with more than one line component in a common network, EMC problems are to be expected. From the start, the installation planner must integrate in his concept high frequency emitted interference as well as the electromagnetic susceptibilityof the components to one another and take measures against it.

Company product range

----------------------Ruichang Mingsheng Automation Equipment Co., Ltd----------------------

PLC module, programmable controller, CPU module, IO module, DO module, AI module, DI module

Network communication module,

Ethernet module, motion control module, analog input module, analog output module, digital input module, digital output

Module, redundancy module, power module, relay output module, relay input module, processor module