Home > Product > Gas turbine system > GE DS200RTBAG4A Gas turbine characteristic module

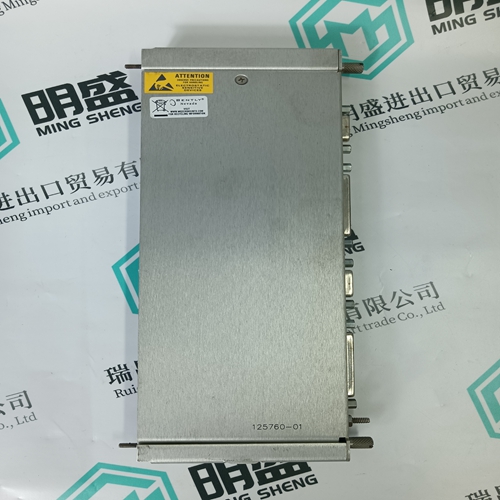

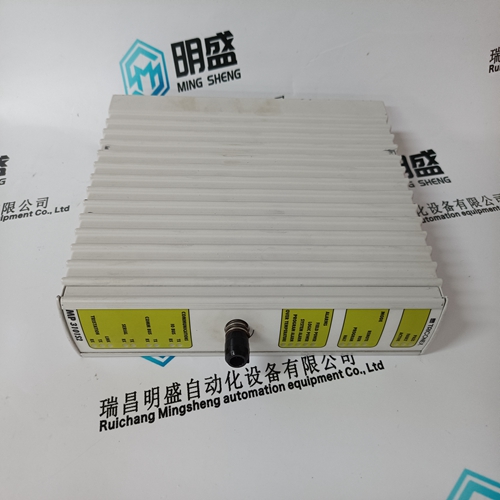

GE DS200RTBAG4A Gas turbine characteristic module

- Product ID: DS200RTBAG4A

- Brand: GE

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:GEDS200RTBAG4AGas turbine characteristic module

- Get the latest price:Click to consult

GE DS200RTBAG4A Gas turbine characteristic module

Introduction More and more frequently, modern beltconveyor systems are equipped with variable-speed drives on the basis of frequency converters connected with standard squirrel-cage motors and gearboxes. As compared with conventional drives used in constant-frequency systems they have the major advantage that both power consumption and mechanical wear can be significantly reduced. This makes it possible, in conjunction with powerful control and process management systems as well as modern diagnostic tools, to design efficient belt-conveyor systems characterised by low operation costs and high availability.

Quality criteria Introducing speed control for belt conveyors

the customer has defined precise economic and technological objectives:

• power savings through a load-dependent control of the belt speed

• efficiency increase • minimisation of system perturbations

• reduction of gear and belt wear

This is the description of such a drive concept covering five belt conveyors implemented recently by ABB. For the first time ABB Automation has used here grid converters according to the latest developments of drive technology.

Demanding quality criteria

have been specified as benchmarks for accomplishing those objectives. They include in particular: • dynamic torque characteristics at starting and stopping

• efficiency with different belt speeds and loads

• power factor (cos ϕ ≥ 0,95)

• system perturbations (THD ≤ 10%) ABB Automation, the supplier of the electrical-engineering part of the system, could successfully prove that all agreed criteria have been attained.

Company product range

----------------------Ruichang Mingsheng Automation Equipment Co., Ltd----------------------

PLC module, programmable controller, CPU module, IO module, DO module, AI module, DI module

Network communication module,

Ethernet module, motion control module, analog input module, analog output module, digital input module, digital output

Module, redundancy module, power module, relay output module, relay input module, processor module