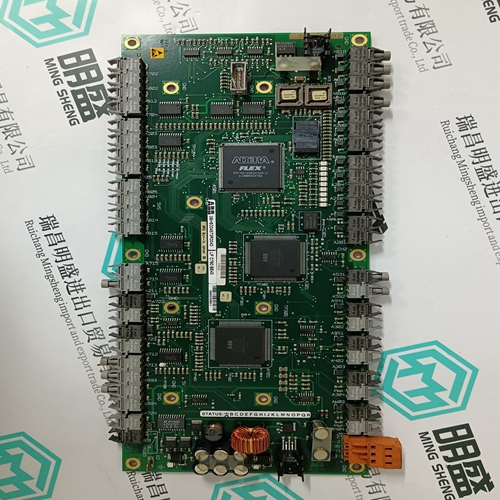

Home > Product > Gas turbine system > GE DS200CVMAG3AEB Sequence control card

GE DS200CVMAG3AEB Sequence control card

- Product ID: DS200CVMAG3AEB

- Brand: GE

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:GEDS200CVMAG3AEBSequence control card

- Get the latest price:Click to consult

GE DS200CVMAG3AEB Sequence control card

In order to procure a motor with attached surface-cooling, the type name of the blower unit must be specified as an ordering subitem of the MKDmotor with the blower arrangement desired.If it is specified as an independent ordering item, the blower unit is delivered separately from the motor (i.e. not attached to the latter).⇒ The serially delivered motor holding brake does not suffice to ensure overall personal protection! ⇒ Ensure personal protection by superordinate failsafe measures: ⇒ Block off the hazardous range by means of a safety fence or a safety screen. ⇒ Additionally secure vertical axes to prevent them from falling or descending after having switched off the motor, for instance as follows: – lock the vertical axis mechanically, – provide an external braking / collecting / clamping device, or – ensure proper weight compensation of the axis.

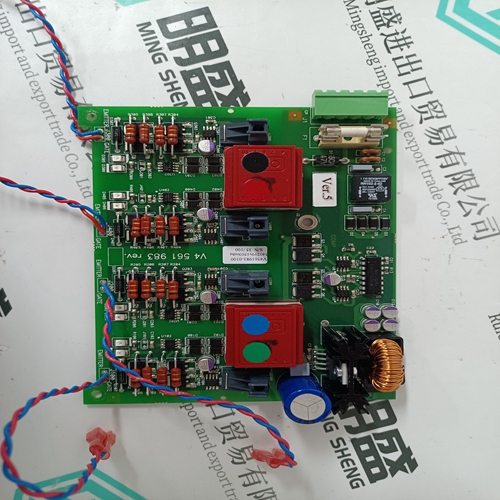

Holding Brakes

Optional. Required for holding the servo axis when the machine is in the de-energized state.The holding brake is operated according to the “electrically releasing” principle. In the de-energized state, a magnetic force acts upon the brake armature disk. This causes the brake to close and to hold the axis. By applying 24 VDC, the permanent magnetic field is compensated by the electrically generated magnetic field: the brake opens.The holding brake is activated by the drive controller. This ensures the proper on and off order in all of the operating states. Note: A premature wear and tear of the holding brake is possible! The holding brake wears after approx. 20.000 motor revolutions in closed state. For that reason, do not use the holding brake as a system brake to stop a moving axis! This is permitted for EMERGENCY STOP situations only. Please observe the instructions on putting the holding brakes into operation described in the chapter entitled “Startup, Operation, and Maintenance”.

Output Shaft and Motor Bearing

Plain shaft The standard design recommended for MKD motors provides a frictionlocked shaft-hub connection without play and excellent running smoothness. Use clamping sets, clamping sleeves or clamping elements to couple the machine elements to be driven. Output shaft with key The optional key according to DIN 6885, Sheet 1, version 08-1968, permits keyed transmission of torques with constant direction, with low requirements for the shaft-hub connection.

Common problem

We have this product in stock, and we can deliver it to you at any time when you need it badly.

*The warranty period of all products is 1 year, which has passed the professional test certification.

*If you need to order more than one product, please contact us, and we can offer you a discount.

*We only use HDL UPS and other express delivery methods to deliver spare parts.

*If you find that other suppliers offer lower prices for the same products, we are also willing to offer you further discounts based on their prices.

If you have any other questions, please feel free to contact us via email.

*Please let us know if you need any spare parts, we can give you further assistance, and we are waiting for your inquiry.