Home > Product > Gas turbine system > GE IS200DSPXH2D Voltage output module

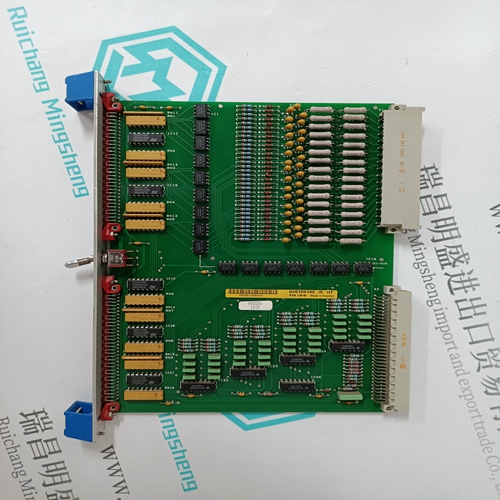

GE IS200DSPXH2D Voltage output module

- Product ID: IS200DSPXH2D

- Brand: GE

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:GEIS200DSPXH2DVoltage output module

- Get the latest price:Click to consult

GE IS200DSPXH2D Voltage output module

• Cut off all phases of power source before installing / removing or performing wiring work on the master in order to avoid electric shock or damage of product.

• After the installation and wiring etc. replace the PLCs top cover before power ON. Note:

• Securely install the expansion board, and fix to the PLC. Defective contact can cause malfunction.

• The tightening torque for fix the board or top cover is 0.3 ~ 0.6 Nxm. Tighten securely to avoid malfunction. Note: Only one expansion board can be used per main unit of FX1S and FX1N PLC. Do not try to install two or more expansion boards. Moreover, the 2AD cannot be used with the FX1N-EEPROM-8L or the FX1N-5DM.

The following is a generic explanation of

how to install a expansion board to the PLC. a) Top cover for expansion board b) M3 self-tapping screw to mount expansion board c) M3 self-tapping screw to fix top cover d) External port for optional equipment e) Expansion board Note: Do not remove this screw. 1) Remove the top cover of the main unit an keep. 2) Plug expansion board “e)” into the external port “d)”. 3) Fix expansion board to main unit using M3 self-tapping screws “c)”. (Tightening torque: 0.3 ~ 0.6N⋅m) 4) Attach top cover for expansion board “a)” removing section “a)’” to expose connector etc. 5) Secure top cover with M3 self-tapping screw “b)”. (Tightening torque: 0.3 ~ 0.6N⋅m)

Cut off all phases of power source

before installing / removing or performing wiring work on the expansion board in order to avoid electric shock or damage of product. Note: • Do not lay signal cable near to high voltage power cable or house them in the same trunking duct. Effects of noise or surge induction may occur. Keep signal cables a safe distance of more than 100 mm (3.94") from these power cables. • Ground the shied wire or the shield of a shielded cable. Do not, however, ground at the same point as high voltage lines. • Never solder the end of any cables. Make sure that the number of connected cables is not more than the unit has been designed for. • Never connect cables of a non permitted size. • Fix cables so that any stress is not directly applied on the terminal block or the cable connection area. • Tighten the terminals to a torque of 0.5 ~ 0.6 Nxm. Do not tighten terminal screws exceeding the specified torque. Failure to do so may cause equipment failures or malfunctions.

Common problem

We have this product in stock, and we can deliver it to you at any time when you need it badly.

*The warranty period of all products is 1 year, which has passed the professional test certification.

*If you need to order more than one product, please contact us, and we can offer you a discount.

*We only use HDL UPS and other express delivery methods to deliver spare parts.

*If you find that other suppliers offer lower prices for the same products, we are also willing to offer you further discounts based on their prices.

If you have any other questions, please feel free to contact us via email.

*Please let us know if you need any spare parts, we can give you further assistance, and we are waiting for your inquiry.