Home > Product > DCS control system > ABB DSMC 110 Automatic card

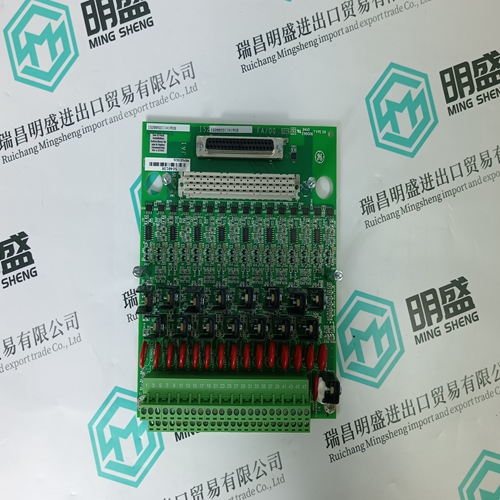

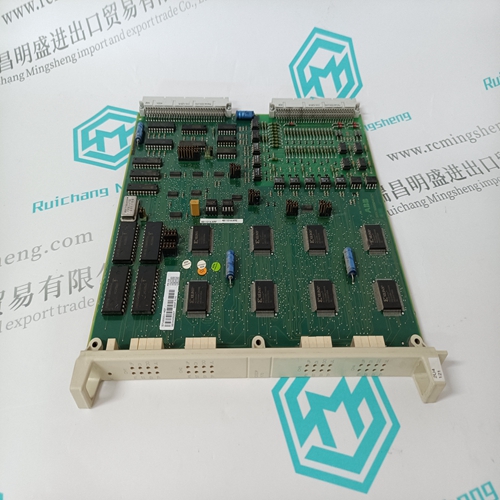

ABB DSMC 110 Automatic card

- Product ID: DSMC 110

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ABBDSMC 110Automatic card

- Get the latest price:Click to consult

ABB DSMC 110 Automatic card

To enable scan time statistics, select ‘Report Statistics’. Enter the Modbus address of an application variable which will be used to send the data to the application in the ‘Data’ field. Select the Statistics Type as appropriate. Depending on the Statistics Type, the variable with the address defined in ‘Control’ has the function described below. The variable may be Boolean or integer. For Max Scan Rate and Average, a falling and rising edge sequence will restart the measurement.The Slave poll scan is defined as the time taken to poll a Slave for all messages in the poll list. The first message defined in the poll list is taken as the start and end point of the timing sequence.

Validation Tool

The Modbus Master Validation Tool is automatically run each time the Modbus Master configuration is saved and exited. The tool may also be run at any time by using the ‘Validate’ button on the Modbus Master main edit page.The Validation Tool scans the current configuration, checking against a rule base which matches the .INI file reader in the CI. Each violation is listed on the Validation Tool window. There is an option to ignore the errors and build the .INI file with the errors still in the configuration. This allows for partial configurations to be saved by the workbench before completion.

The rules used by the Validation Tool are listed below.

• All control registers used must be unique for all Master and Slave devices. • All status registers used must be unique for all Master and Slave devices. • If a Master is using Ethernet communications there must be a valid IP address specified which is not 0.0.0.0. • No two Master devices can use the same Serial port. • All Slave devices connected to a common Master must have unique station IDs. • Two or more messages cannot write to the same application variable. • Broadcast Mode control variables must be unique for all Master devices. • When using single shot broadcast mode, a control variable must be defined. • All statistics control and data variables must unique for all Master and Slave devices.

Our superior products

ABB -- AC 800M controller, Bailey, PM866 controller, IGCT silicon controlled 5SHY 3BHB01 3BHEO0 3HNA00 DSOC series

BENTLY --- 3500 system/proximitor, front and rear cards, sensors, power modules, probes, cables

Emerson -- modbus card, power panel, controller, power supply, base, power module, switch

EPRO --- Data acquisition module, probe, speed sensor, vibration sensor, shaft vibration transmitter, proximitor

FOXBORO - thermal resistance input/output module, power module, communication module, cable, controller, switch

GE --- module, air switch, I/O module, display, CPU module, power module, converter, CPU board, Ethernet module, integrated protection device, power module, gas turbine card

HIMA --- DI module, processor module, AI card, pulse encoder

Honeywell --- Secure digital output card, program module, analog input card, CPU module, FIM card

MOOG - servo valve, controller, module, power module

NI --- Information acquisition card, PXI module, card, chassis multi-channel control card

WESTINGHOUSE --- RTD thermal resistance input module, AI/AO/DI/DO module, power module, control module, base module

Woodward - Regulator, module, controller, governor

YOKOGAWA - Servo module, control cabinet node unit