Home > Product > DCS control system > PM864A 3BSE018162R1 Control processor

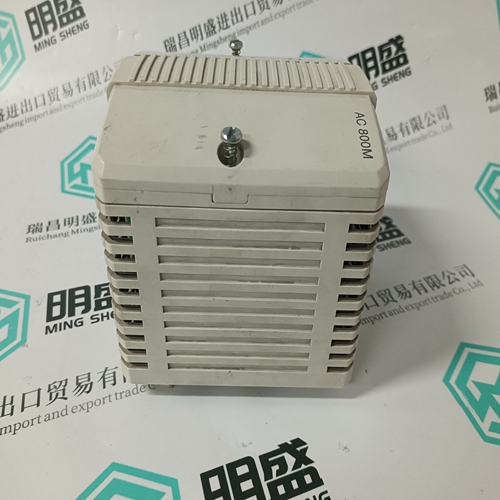

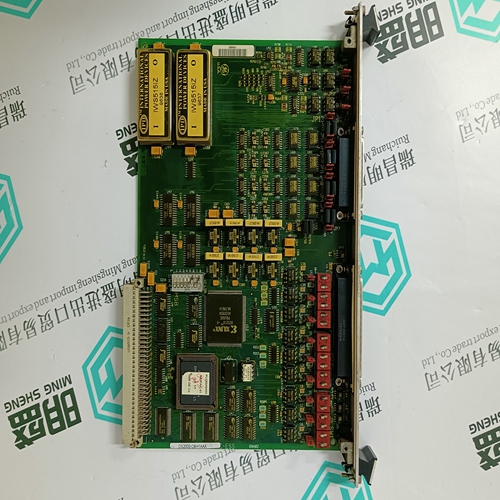

PM864A 3BSE018162R1 Control processor

- Product ID: PM864A 3BSE018162R1

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:PM864A 3BSE018162R1Control processor

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

PM864A 3BSE018162R1 Control processor

Faults in the machine or the facility can have very different causes. Drive movements can be effected by faults in the following areas: 1. Mechanical coupling or transmission elements at the motor shaft (loose, elasticity, conversion, moments of inertia, jams, friction) 2. Mechanical stability of the machine’s frame (rigidity) 3. Position measuring systems, position encoder 4. Numerical control (NC, CNC) 5. Other controllers (SPS) 6. Driving systems with – supply modules – drive modules – motor cables – motor with feedback electronics 7. Mains connections with transformers, throttles and controller loops with contactors and auxiliary relays. 8. Conditions of the electrical mains 9. Electromagnetic influences caused by equipment or machinery working with frequencies higher than the mains frequency, or the use of large amounts of energy. The machine user should first check the fault messages at the terminal strip (cross-section) of the module in the event of a problem. These signals can easily be evaluated directly at the controller and are displayed on the control panel. There is an overview of interface signals in Fig. 80.

Fault messages at the terminal strips

The Bb1 contact of the supply module is integrated, in accordance with the recommended controller description, to the supply unit in the emergency-off loop. The Bb contact of the servo drive module for activating the mains feed is also then used if the commissioning current needs to be restricted with the use of resistors (only applies to supply modules TVM1, TVM2 and KDV1). In the presence of either a mains fault or a mains failure, or if emergency off is activated, then this fault message is generally transmitted to the drive module via cable X1.1. There it brings about a deceleration of the connected drives and the internal switching off of the controller enable after approximately 300 ms. It is possible in the case of some of the supply units (not with TVM1, TVM2 and KDV1) to have the NC, with a clamped on NCB bridge, brake the attached drives in either an emergency off situation or with a power failure. This obstructs the transmission of the signal via X1.1.

The prerequisite, in this case, is that the occurring braking energy of all the mounted drives is greater than the energy expended by the motor for the feedback action conducted by the NC and the link circuit output for the signal electronics. It is not permissible to conduct the controller enable over the auxiliary contact of the mains contactor as it would, in this case, be immediately shut down. It must always be guaranteed, even with a closed NCB bridge, that the drives can be shut down in the event of a fault - even in the NC.