Home > Product > PLC programmable module > ICS TRIPLEX T9110 Communication module

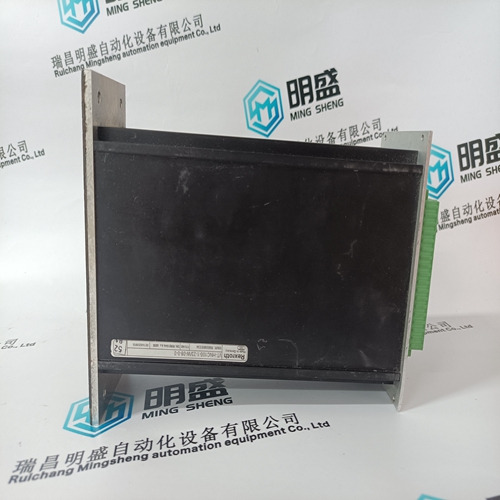

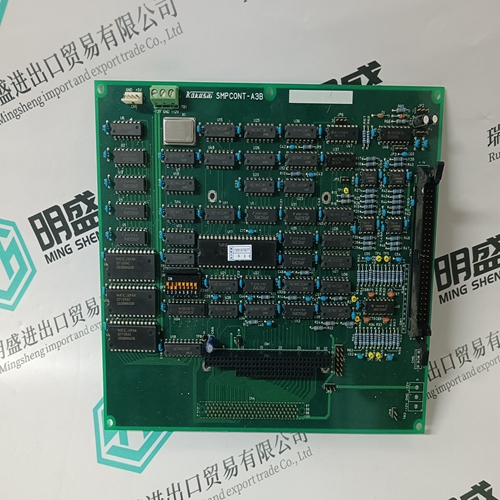

ICS TRIPLEX T9110 Communication module

- Product ID: T9110

- Brand: ICS TRIPLEX

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ICS TRIPLEX T9110Communication module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

ICS TRIPLEX T9110 Communication module

Possible fault causes and measures: – Only applies to KDV3 and KDV4: No mains auxiliary power at supply module input ➞ Check mains connection for auxiliary power – Short-circuit in the signal electronics in at least one of the connected drives (in drive module, feedback cable, or motor feedback). ➞ Remove the individual line connectiions (bus connection X1, feedback cable, wiring on the terminal strips) and then ➞ measure the 24V, plus/minus 15V voltages at the connection points or terminals and, in this way, begin to limit the fault (generally shortcircuit). – Maximum load of the control voltage plus/minus 15 V or 24 V is being exceeded. ➞ Check current load via the connected drives in accordance with the data sheet (current input). – Only applies to KDV3 and KDV4: Defective unit fuse in the supply module ➞ check fuses, ➞ if fault remains, find the fault on the 24 volts or in the fans, and eliminate it, ➞ put in new fuses.

Check rotational field direction at connecting terminals L1, L2, L3 of the supply module (e.g., using rotational field measuring equipment or the succession of phases with an oscilloscope). If there is no right rotational field, then exchange lines L1 and L2 on the supply module.

Notes on Equipment Replacement

Time consuming searches for the faults within the individual units or the repair of the units within the machine are not acceptable because of the loss in production that these represent. The diagnostic displays and the fault signals at the controller interfaces of INDRAMAT’s AC Drives make a to-the-point and effective troubleshooting possible. Once a drive component such as the supply module, drive amplifier module, motor or cable is diagnosed as defective, it can be exchanged without any problem. This makes a speedy elimination of the problem and a resumption of operation without drawn out assembly and adjustment work possible. The factory-ready and optimized programming module MOD makes this adjustment-free exchange possible. The following should be noted when exchanging a component: – The new unit, motor or cable must have the exact same type designation on its rating plate as the one that is being replaced. – In the case of a servo drive module (generally not defective), programming module MOD should be removed from the defective unit and plugged into the replacement drive module. – The drift must be checked when exchanging the servo drive module, in accordance with Chapter 2.1, keyword „Drift Alignment“.