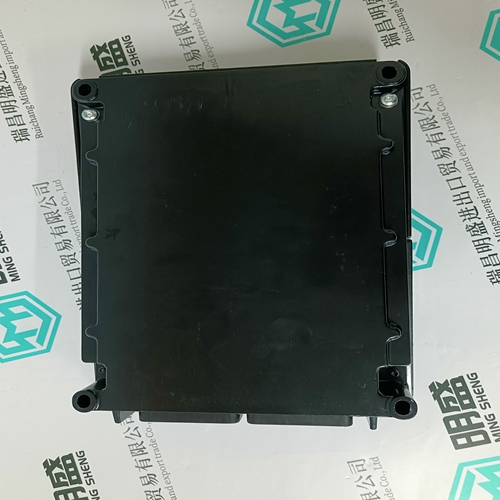

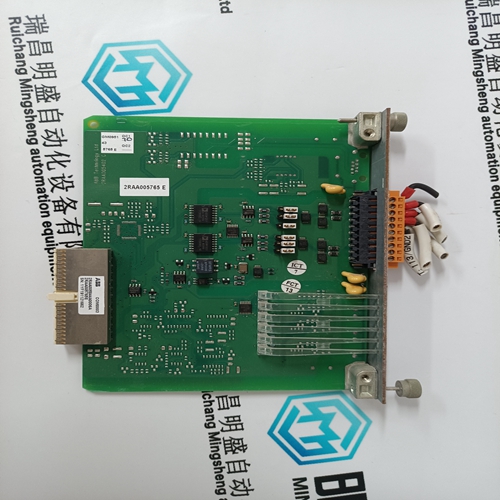

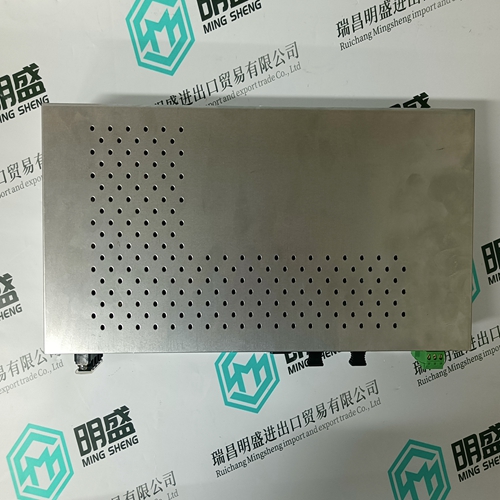

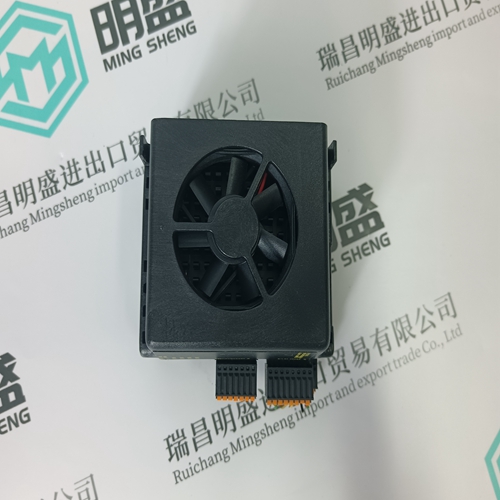

Home > Product > Servo control system > WOODWARD 8237-1006 servo controller

WOODWARD 8237-1006 servo controller

- Product ID: 8237-1006

- Brand: WOODWARD

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:WOODWARD 8237-1006servo controller

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

WOODWARD 8237-1006 servo controller

In those cases where it suffices to switch off power to protect the facility from damage, e.g., overrunning the final limit switch or a problem in the drive electronics. Typical application: • the KDV 4.1supplies only asynchronous drives, and, • the final limit switches of the feed axes are sufficiently damped. Power off occurs simultaneously with actuation of emergency stop. The energy contained in the drives is transformed into heat. The KDV 4.1 bleeder resistor can take up a maximum of 100 kWs over a five minute period. The powering down of the drives takes precedence over protecting the bleeder resistor against overload. Frequent consecutive and arbitrary emergency stops (e.g., commissioning) can damage the KDV 4.1 and are not permitted. The dc-bus voltage is not short-circuited. The dc-bus short circuit has no additional braking effect on asynchronous drives if there is a problem with the drive electronics. There will be no controlled braking of the drives if the dc-bus is short-circuited. There will be a controlled braking of the drives by the drive electronics at maximum torque in an emergency stop or with a message from the control monitors in the KDV 4.1 (e.g., power failure).

The power contactor is immediately turned off once the emergency stop sequence is initiated. The controller enable signals of the drives are also switched off by an auxiliary contact of the power contactor. This causes the set-point value of all attached drives to switch to zero. There is a controlled braking of all drives.

Operating characteristics

The drive enable signal is immediately turned off once the emergency stop sequence is initiated. This causes a set-point value of all attached drives to switch to zero. There is a controlled braking of all drives. Powering down is delayed for the time it takes to brake the asynchronous drives. Both the power and the controller enable signals of the drives are immediately switched off if there is a drive fault signal from the KDV 4.1 (Bb1-contact) a fault message from the CNC controller (servo-fault), or if the final limit switch is overrun. A delayed powering down is necessary if the danger of a thermal overload of the bleeder resistor due to excessive energy content is present. The bleeder resistor can be loaded with a maximum of 100 kWs over a five-minute period. Typical application: • the KDV 4.1only supplies asynchronous drives, and, • the final limit switches of the feed axes are sufficiently damped. The first thing to happen once the emergency stop is actuated is a braking of the drives. There is a delay in power shutdown. The energy contained in the drives is fed back into the mains. Drive energy is only then transformed into heat if there is a power failure or drive trouble. DC-bus voltage is not short-circuited. The dc-bus short circuit has no additional braking effect on asynchronous drives when there are problems with the drive electronics. There will be no controlled braking of the drives, if the dc-bus voltage is short-circuited. There will be a controlled braking of the drives by the drive electronics at maximum torque in the event of an emergency stop or a signal from the control monitors in the KDV 4.1 (e.g., power failure)