Home > Product > PLC programmable module > 531X305NTBAPG1 F31X305NTBAPG1 MRP375547 Gas turbine module

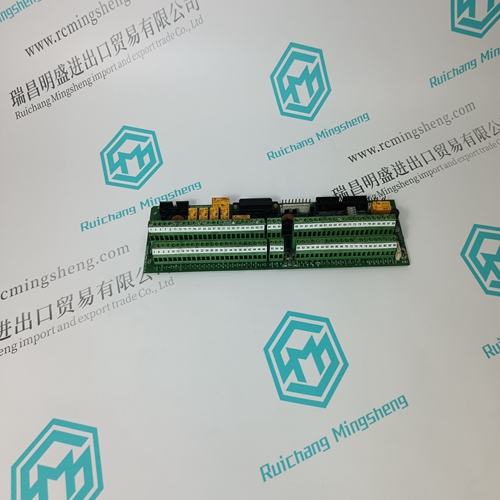

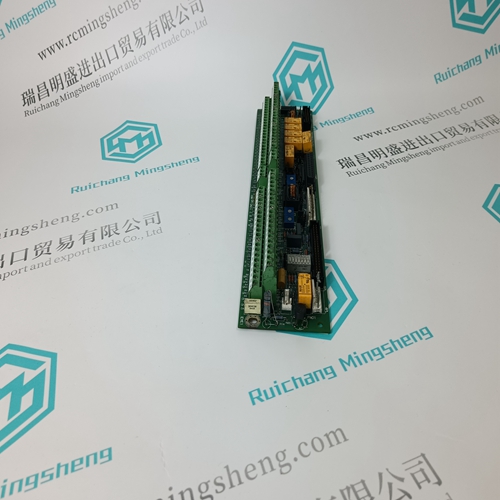

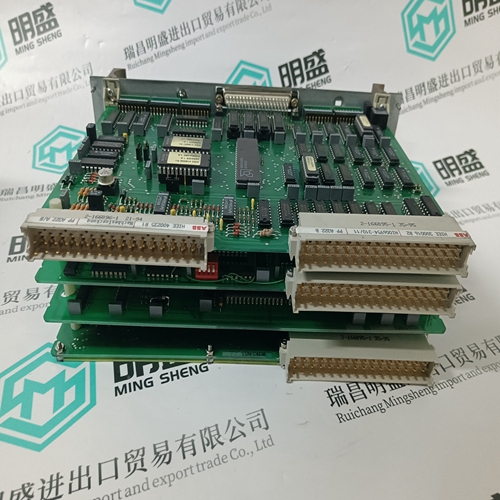

531X305NTBAPG1 F31X305NTBAPG1 MRP375547 Gas turbine module

- Product ID: 531X305NTBAPG1 F31X305NTBAPG1 MRP375547

- Brand: GE

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:531X305NTBAPG1 F31X305NTBAPG1 MRP375547Gas turbine module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

531X305NTBAPG1 F31X305NTBAPG1 MRP375547 Gas turbine module

Can cause death or injury • Remove power from all wires and terminals before working on equipment. • In potentially hazardous atmosphere, remove power from equipment before connecting or disconnecting power, signal, or other circuit. • Observe all pertinent regulations regarding installation in hazardous area.

11.1 TOOLS AND TEST EQUIPMENT The following tools and equipment are necessary for servicing: A. Common hand tools for servicing electronic equipment B. Digital Multimeter (DMM) Voltmeter Section: Accuracy +/-0.01% of reading Resolution 1.0 millivolt input Impedance 10 Megohms Ammeter section: Accuracy +/- 0.1% of reading Resolution 100 microamperes C. Maintenance Kit, P/N 15545-110, containing wrist strap and conductive mat. This kit or an equivalent is required when a circuit board assembly is handled for any reason.

11.2 PREVENTIVE MAINTENANCE

The objective for establishing a preventive maintenance program is to provide maximum operating efficiency. Every preventive maintenance operation should assist in realizing this objective. Unless a preventive measure reduces a Station’s down time, it is unnecessary. 11.2.1 Environmental Considerations The controller has been designed to operate within specified environmental parameters (temperature and humidity). These parameters are listed in the Model Designation and Specifications section of this User’s Manual. Additional information concerning environmental contaminants is covered in the Installation section. 11.2.2 Visual Inspection As part of a periodic maintenance program, the controller should be visually inspected. When viewing the station, scan for abnormalities such as loose, broken or stressed ribbon cables. Look for damaged circuitry and heat stressed parts. Check for excessive dirt or dust build-up which may impede air flow and inhibit proper heat dissipation. 11.2.3 Cleaning Circuit boards are conformally coated for protection against contaminants and should not be cleaned unless accumulated foreign material is causing a problem. If cleaning becomes necessary: 1. Protect the station’s electronic components from electrostatic discharge . Fasten a conductive wrist strap around your wrist and ground the strap to the station’s case, the panel, or a static dissipative workmat. See the next section for circuit board handling guidelines. 2. Loosen the Display Assembly’s two faceplate screws. One screw is above the numeric display, the other behind the flip-down door at the bottom of the faceplate. See Figure 11-1 as needed. 3. Pull the Assembly from the panel about 1.5" (38 mm).