Home > Product > DCS control system > HONEYWELL 51405040-175 CC-PDIL01 Automation spare parts

HONEYWELL 51405040-175 CC-PDIL01 Automation spare parts

- Product ID: 51405040-175 CC-PDIL01

- Brand: HONEYWELL

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:HONEYWELL51405040-175CC-PDIL01Automation spare parts

- Get the latest price:Click to consult

HONEYWELL 51405040-175 CC-PDIL01 Automation spare parts

Be sure that the 16XBug memory devices are installed in proper sockets on the MVME16X module. Refer to the boardspecific debugger manual for details. 4. Refer to the set-up procedure for your particular chassis or system for details concerning the installation of the MVME16X. 5. Connect the terminal which is to be used as the 16XBug system console to the default debug EIA-232-D port at the proper location described in the MVME16X installation manual or the 16XBug board-specific debugger manual. Set up the terminal as follows: – Eight bits per character – One stop bit per character – Parity disabled (no parity) – Baud rate 9600 baud (default baud rate of MVME16X ports at power-up) After power-up, the baud rate of the debug port can be reconfigured by using the Port Format (PF) command of the 16XBug debugger.

If you want to connect devices

(such as a host computer system and/or a serial printer) to the other EIA-232-D port(s), connect the appropriate cables and configure the port(s) as detailed in step 5 above. After power-up, this (these) port(s) can be reconfigured by programming the MVME16X serial interface chip, or by using the 16XBug PF command. Note that some MVME16X modules contain parallel ports. To use a parallel device, such as a printer, with such an MVME16X module, connect it to the appropriate parallel port per the installation manual for the MVME16X module. However, with any MVME16X, you could add a module such as the MVME335 to the system.

Power up the system.

16XBug executes some self-checks and displays the debugger prompt "16X-Bug>" (if 16XBug is in Board Mode). However, if the ENV command has put 16XBug in System Mode, the system performs a selftest and tries to autoboot. Refer to the ENV and MENU commands in Chapter 3, and to system operation in Appendix A. If the confidence test fails, the test is aborted when the first fault is encountered. If possible, an appropriate message is displayed, and control then returns to the menu.being used does not do hardware handshaking via the CTS line, then it must do XON/XOFF handshaking. If you get garbled messages and missing characters, then you should check the terminal to make sure XON/XOFF handshaking is enabled.

Application industry

Our main products are widely used in metallurgy, oil and gas, glass manufacturing, aluminum, petrochemical, coal mine, paper making and printing, textile printing and dyeing, machinery, electronic manufacturing, automobile manufacturing, tobacco, plastic machinery, electricity, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution, etc.

Superior products

We mainly make spare parts for DCS, PLC, robot control system and large servo system.

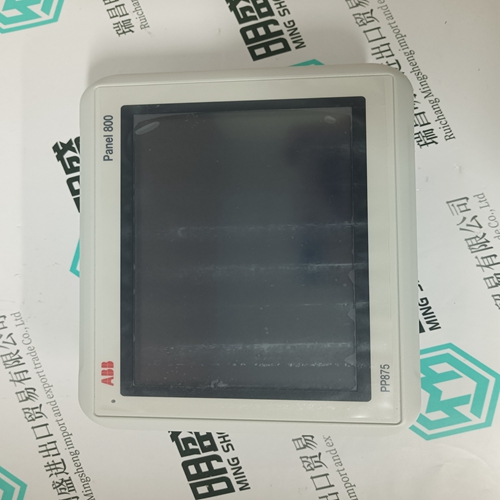

Main products: various modules/cards, controllers, touch screens, servo drives.

Advantages: professional off production accessories,

Fast delivery, accurate delivery time,

Main brands include ABB, GE/FANC, FOXBORO, TRICONEX, BENTLY NEVADA, A-B, EMERSON, OVATION, MOTOROLA, XYVOM, HONEYWELL, REXROTH, KUKA, NI, DEIF, Reliance Electric, Yokogawa, WOODWARD, SCHNEIDER, MOOG, PROSOFT and other brands