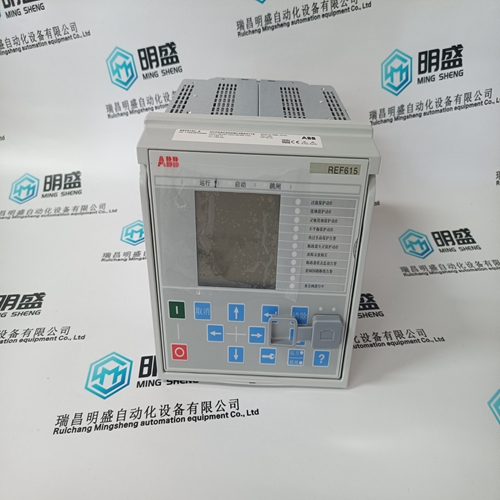

Home > Product > DCS control system > TRICONEX 2301 base module

TRICONEX 2301 base module

- Product ID: 2301

- Brand: TRICONEX

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:TRICONEX 2301base module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

TRICONEX 2301 base module

In the Advant Controller 400 Series up to about 4000 DSPs can be configured on one bus. The configuration routines are heavy to execute, especially in combination with bus mastership. Configuring DSPs in the Advant Controller 400 Series takes about seven seconds per 100 DSPs if several Bus Administrators are used. In case of just one Bus Administrator the configuration time is about the double. When a DSP is to be configured there must be room for it in the communication interface scan table. In case the scan table can not house the CDP configuration overload has occurred, the CDP is not configured and by this not transferred on the bus. Further configurations of the communication interface will also fail due to configuration overload. For calculation of the configuration load see Chapter 3.6.1 DataSet Peripheral Transfer Time. In the Advant Controller 400 Series a DSP’s DIAG terminal will show SNC (Signal Not Configured) for a configuration overload.

The sending DSP is defined in station 15. Data from this element is transmitted on the AF 100 every 64 millisecond. In station 21, the receiving DSP receives data from station 15 (every 64 millisecond). The DSP VALID flag is set in station 15 the first update of the bus (send) and in station 21 when read from the bus (receive).

Configuring DataSet Peripherals

At start up of the system the DSP data base definition is configured on the communication interface. For each DSP a corresponding CDP is configured. Receiving DSPs are immediately operational and able to receive data from the Advant Fieldbus 100. For sending DSPs all the connected communication interface must be informed about the change in the configuration in order to regenerate their scan tables. At configuration, a scan table is built up containing the sending CDPs, configured on the associated communication interface and the current scan table working on the bus, if any. When the configuration is performed the new scan table is transferred to all Bus Administrator communication interfaces on the bus. By this all communication interfaces, defined as masters, have knowledge of all configured sending CDPs on the bus. Each CDP in the scan table is owned by the station number of the communication interface on which it was configured. Any reconsideration of the CDP such as size, signal identity, delete etc. is to be done by the owner communication interface unless the station number is changed.

A consequence of this is that a change of the communication interface station number might result in CDPs not owned by any communication interface, orphan CDPs. Orphan CDPs is a source of failed configuration that can be tricky to handle. Before change of station number or removal of a station from the bus, all CDPs configured on the current communication interface should be deleted. The most definite way to delete orphan CDPs is to reset the current scan table, that is to reset the IMPL terminal on each communication interfaces on the bus defined as busmaster. The bus is by this stopped. The scan table is then built up from the beginning when the IMPL terminals are set again.