Home > Product > DCS control system > ABB DDO01 Serial Link Module

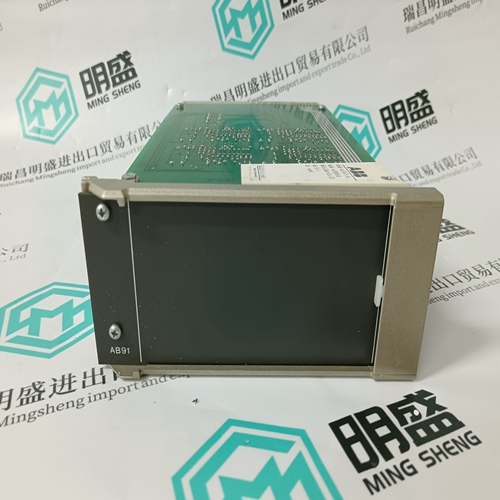

ABB DDO01 Serial Link Module

- Product ID: DDO01

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ABBDDO01Serial Link Module

- Get the latest price:Click to consult

ABB DDO01 Serial Link Module

There is a danger of electrical arcing with damage to contacts and serious personal injury. Capacitors can still have dangerous voltages present up to 5 minutes after switching off the supply power. Control and power connections can still be live, even if the motor is not rotating. Only install and wire the equipment when it is not live. Make sure that the cabinet is safely disconnected (for instance, with a lock-out and warning signs). Never remove electrical connections to the drive while it is live. Wait at least 5 minutes after disconnecting the drive from the main supply power before touching potentially live sections of the equipment (e.g. contacts) or undoing any connections. To be sure, measure the voltage in the DC bus link and wait until it has fallen below 50 V.

With SERVOSTAR 640/670 external

mains chokes and mains filters are required. Excessively high external fusing will endanger cables and devices. The fusing of the voltage supply must be installed by the user, best values (➜ # 54). Hints for use of Residual-current circuit breakers (FI) see Instructions Manual. Route power and control cables separately. We recommend a distance of at least 200 mm. If a motor power cable is used that includes cores for brake control, the brake control cores must be separately shielded. Ground the shielding at both ends. Ground all shielding with large areas (low impedance), with metalized connector housings or shield connection clamps wherever possible.

Feedback lines may not be extended

since thereby the shielding would be interrupted and the signal processing could be disturbed. Lines between servo amplifiers and filter or external brake resistor must be shielded. Install all power cables with an adequate cross-section, as per IEC 60204. The servo amplifier's status must be monitored by the PLC to acknowledge critical situations. Wire the BTB/RTO contact in series into the emergency stop circuit of the installation. The emergency stop circuit must operate the supply contactor.

Superior products

ABB -- AC 800M controller, Bailey, PM866 controller, IGCT silicon controlled 5SHY 3BHB01 3BHEO0 3HNA00 DSOC series

BENTLY --- 3500 system/proximitor, front and rear cards, sensors, power modules, probes, cables

Emerson -- modbus card, power panel, controller, power supply, base, power module, switchEPRO --- Data acquisition module, probe, speed sensor, vibration sensor, shaft vibration transmitter, proximitor

FOXBORO - thermal resistance input/output module, power module, communication module, cable, controller, switch

GE --- module, air switch, I/O module, display, CPU module, power module, converter, CPU board, Ethernet module, integrated protection device, power module, gas turbine card

HIMA --- DI module, processor module, AI card, pulse encoder

Honeywell --- Secure digital output card, program module, analog input card, CPU module, FIM cardMOOG - servo valve, controller, module, power module

NI --- Information acquisition card, PXI module, card, chassis multi-channel control card

WESTINGHOUSE --- RTD thermal resistance input module, AI/AO/DI/DO module, power module, control module, base module

Woodward - Regulator, module, controller, governor

YOKOGAWA - Servo module, control cabinet node unit