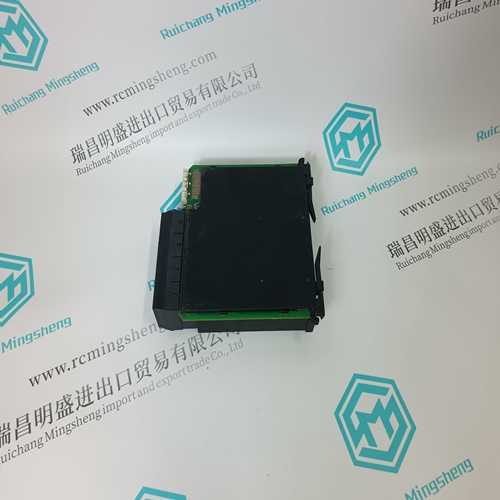

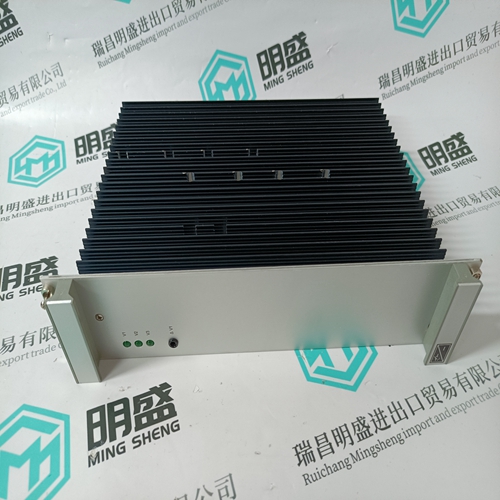

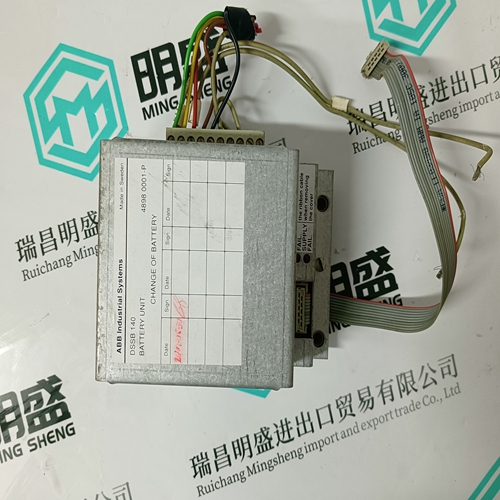

Home > Product > DCS control system > ABB YB161100-KR Channel output module

ABB YB161100-KR Channel output module

- Product ID: YB161100-KR

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ABBYB161100-KRChannel output module

- Get the latest price:Click to consult

ABB YB161100-KR Channel output module

Cartridge DDR Features

• Assembles as quickly as 5 minutes

• 5 frame sizes, multiple lengths

• Continuous torque range: 4.57 Nm (3.37 lb-ft) to 510 Nm (373 lb-ft), accommodates a wide range of high-power application requirements

• Optimized torque output with high-pole count efficient electromagnetic design

• Integrated high-resolution sine-encoder

• 134,217,728 counts/rev

• Speeds up to 2,500 RPM meets most medium speed and high-torque application requirements

• Meets high power demands of most frameless motor applications

• Direct load connection eliminates maintenance of gearheads, belts, or pulleys

• Low cogging for smooth low-speed rotation

• Zero backlash and compliance provides more responsive system performance

The Cartridge DDR Advantage – Press Feed Machine

Consider how Cartridge DDR technology improves a Press Feed machine:The assembly time for the original mechanical transmission system was 4 hours. In contrast, the Cartridge DDR motor is installed in less than 5 minutes, resulting in a significant cost savings in labor.The Cartridge DDR system eliminates parts that wear, change over time, or fail. Gearheads are prone to wear, and backlash increases over time. Belts and pulleys stretch and require maintenance to maintain proper belt tension. By eliminating these components, the Cartridge DDR system delivers greater system reliability.

Gearheads have a finite life span

especially in a demanding cyclic Reduced Parts Count application such as a Press Feed. On this machine, the gearhead must be replaced every 10,000 hours and the belt must be tensioned The original mechanical transmission system comprises 2 bracket every 2,000 hours. By contrast, the Cartridge DDR motor has no pieces, 12 bolts, 2 pulleys, 2 set screws, 2 keys, a timing belt, a wear components and requires no maintenance thus simplifying the housing to protect operators from the timing belt, a tension system for maintenance schedule for the machine, including operating costs. the timing belt, and motor/gearhead. With the Cartridge DDR system, this is all replaced by the motor and 4 mounting bolts, resulting in fewer parts to maintain and cost savings

Our products

A company specializes in the sales of module spare parts of global famous brands (DCS system) (robot system) (large servo control system). The company's products include distributed control system (DCS), programmable controller (PLC), MOTOROLA MVME industrial module, industrial control communication converter (Anybus), remote output/input module (RTU), industrial computer (IPC), industrial low screen screen (IPC) HMI SCSI (50, 68, 80Pin) AnyBus (Gateway) has become a global sales enterprise of industrial automation spare parts and components

Payment method and delivery

Shipment: EMS,DHL,UPS & FEDEX

Payment: T/T or Western Union