Home > Product > DCS control system > ABB YB161102-AE S2 DSQC104 Integrated circuit module

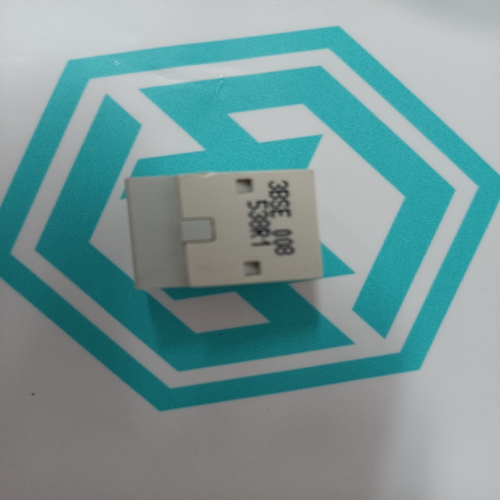

ABB YB161102-AE S2 DSQC104 Integrated circuit module

- Product ID: YB161102-AE S2 DSQC104

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ABBYB161102-AE S2DSQC104Integrated circuit module

- Get the latest price:Click to consult

ABB YB161102-AE S2 DSQC104 Integrated circuit module

Kollmorgen offers electric cylinder drive mechanisms designed around either lead or ballscrews. Ballscrews, being the more efficient of the two, utilize ball nuts riding on recirculating ball bearings, resulting in higher speeds, loads and cycle rates. However, the more efficient design of ballscrew technology lends it to being backdriven when power is removed if precautions are not taken (e.g., electric brakes or counter loading). Lead screws are capable of holding the load in position when power is removed, but are less efficient in operation. Kollmorgen’s guide system prevents rotation of the drive nut, thus eliminating any torque loading to machine linkage.

Electric Cylinders Are Preferred When

• Positioning an externally guided and supported load

• Moving a load that pivots

• There is a high concentration of airborne contaminants (rodless actuators are inherently less well protected)

• Replacing a hydraulic or pneumatic cylinder with an electromechanical solution

Rodless Actuators R-Series

The name “Rodless Actuator” comes from this technology’s close relationship to Electric Cylinders, sharing many of the same components. Rather than having a rod, Rodless Actuators incorporate a carriage supported by linear bearings. Where Electric Cylinders are designed to extend in and out of the work area delivering force or thrust, Rodless Actuators are designed to be load carrying mechanisms (up to 300 lb) incorporating ballscrews, leadscrews, or belt drive transmissions with optional integrated gearheads. Rodless Actuators also share many of the fundamental design characteristics of Precision Positioning Tables. Precision Tables are designed to carry larger payloads and deliver superior repeatability and accuracy. Rodless Actuators offer longer travels and higher speeds at a lower price. Screw driven Rodless Actuators are also thrust-producing devices that are best for axial force applications where the space is limited and a payload must also be supported or carried. As individual components, Rodless Actuators are not well suited for moment loading; however, they can be effectively combined into complete Cartesian Systems for some multi-axis applications. For higher speed, lower thrust applications, Rodless Actuators can be repeatabilitydriven with a timing belt instead of a screw

Our products

A company specializes in the sales of module spare parts of global famous brands (DCS system) (robot system) (large servo control system). The company's products include distributed control system (DCS), programmable controller (PLC), MOTOROLA MVME industrial module, industrial control communication converter (Anybus), remote output/input module (RTU), industrial computer (IPC), industrial low screen screen (IPC) HMI SCSI (50, 68, 80Pin) AnyBus (Gateway) has become a global sales enterprise of industrial automation spare parts and components

Payment method and delivery

Shipment: EMS,DHL,UPS & FEDEX

Payment: T/T or Western Union