Home > Product > DCS control system > ABB 3BSE016323R3 Displacement speed clamp

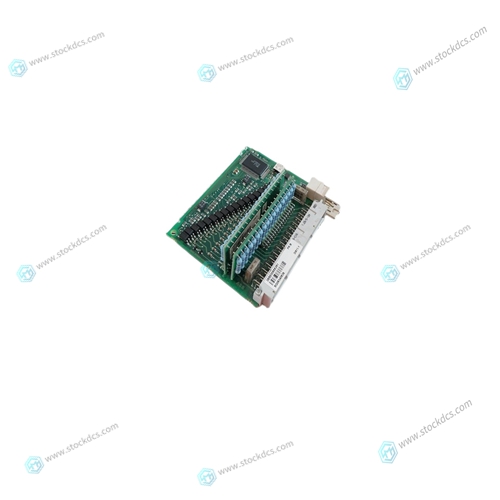

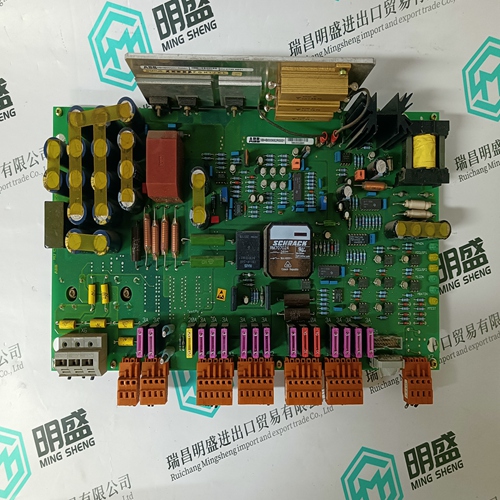

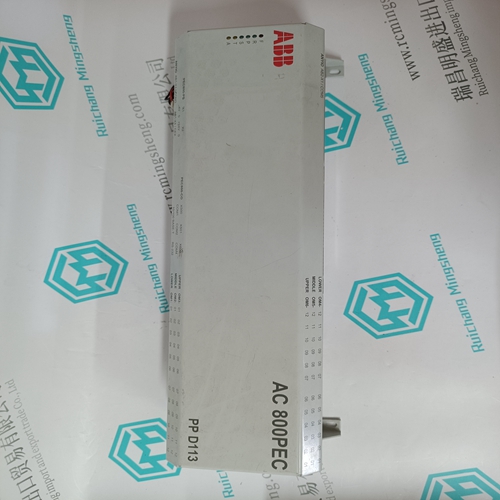

ABB 3BSE016323R3 Displacement speed clamp

- Product ID: 3BSE016323R3

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ABB3BSE016323R3Displacement speed clamp

- Get the latest price:Click to consult

ABB 3BSE016323R3 Displacement speed clamp

Shielded wires to be twisted pairs or twisted 3-conductor, grounded at one end only. 2. 4 or 2 mm² (12 or 14 AWG) stranded wire, must be as short as possible. Total of distance from battery to control, and from control to actuator, to be as short as possible (see maximum length in chart). 3. See EPG Models above for source voltages. 4. Open for minimum fuel. Do not use either the minimum fuel option, or disconnect the actuator leads, or disconnect the power to the control as part of any emergency stop sequence. 5. For positive ground systems, switch and fuse to be located in series with battery (–) and terminal 2. Positive (+) terminal becomes chassis ground. Leads from battery to terminals 1 and 2 must be direct and not pass through distribution points. 6. Approximate speed change with trim potentiometer: ±2.5% using a 1 kΩ potentiometer ±5% using a 2 kΩ potentiometer

Polarity not important.

With a balanced load and unity power factor (PF=1), the current transformer should be wired in the correct potential leg, and must be phased at the control so the potential at terminal 9 to 10 is in phase with the CT from terminal 11 to 12. 12. Power source current transformers should be sized to produce a 5 A secondary current, with maximum generator current. CT burden is essentially 0 VA. 13. Absolute minimum signal must be 95 Vrms. Absolute maximum signal must be 260 Vrms. Potential transformer burden is 20 VA. 14. This control contains an internal current transformer. This transformer must be connected across the power source transformer whenever the unit is running to prevent lethal high voltage from developing on leads to these terminals. 15. On systems without a neutral, the voltage at terminal 9 to 10 is 1.73 times N2/N1 times the line-to-line voltage.

Speed Control

The speed control box should be mounted on the control panel, often on the same skid as the engine. It is not designed for installation on the engine. Provide space for adjustment, wiring access, and ventilation. Choose a location that protects the control from being bumped and that the wiring harness will reach. The installation should allow for adequate air circulation to the control box and have an ambient temperature of –40 to +75 °C (–40 to +167 °F).

Our products

A company specializes in the sales of module spare parts of global famous brands (DCS system) (robot system) (large servo control system). The company's products include distributed control system (DCS), programmable controller (PLC), MOTOROLA MVME industrial module, industrial control communication converter (Anybus), remote output/input module (RTU), industrial computer (IPC), industrial low screen screen (IPC) HMI SCSI (50, 68, 80Pin) AnyBus (Gateway) has become a global sales enterprise of industrial automation spare parts and components

Payment method and delivery

Shipment: EMS,DHL,UPS & FEDEX

Payment: T/T or Western Union