Home > Product > Robot control system > VT-HNC100-1-23/W-08-P-0 R900958999 Driver module

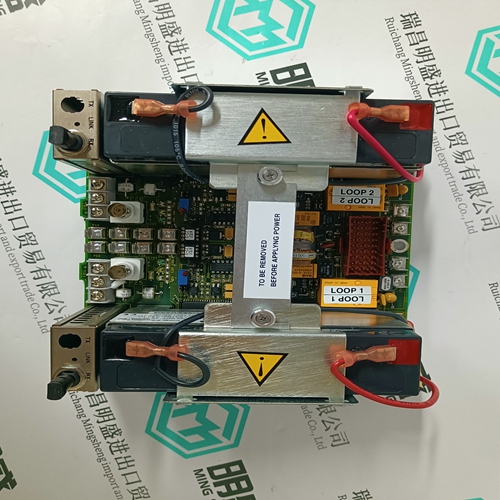

VT-HNC100-1-23/W-08-P-0 R900958999 Driver module

- Product ID: VT-HNC100-1-23/W-08-P-0 R900958999

- Brand: REXROTH

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:VT-HNC100-1-23/W-08-P-0R900958999Driver module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

VT-HNC100-1-23/W-08-P-0 R900958999 Driver module

Automatic gas burner control for one-stage burners with pilot burner or direct ignition • Continuous operation • Confi gurable program sequence • Version with or without display • Two independent fl ame detectors: Ionisation input Gate input • Additional functions by extension modules • Profi bus • Accessories Flame detector Ignition transformers Parameterisation and service box

Description Microprocessor-controlled automatic gas burner control for intermittent and continuous operation of one-stage atmospheric burners or one-stage or modulating fanned burners. The program sequence and times can be customised by setting software parameters. Versions • MPA 4111 without display • MPA 4112 with integrated display • MPA 4122 with metal housing and integrated display Application For one-stage or modulating gas burners with or without ignition gas. In particular for industrial thermoprocessing equipment to EN 746-2.

Approvals EC type-examination certifi cate according to the EC Gas Appliances Directive: MPA 41xx CE-0085BU 0487 EC type-examination certificate according to the EC Pressure Equipment Directive: MPA 41xx CE0036 FM Approved to FM 761 UL Recognized Component per UL 372, UL 1998 and CSA C22.2. GOST / Rostechnadzor Suitable for applications up to SIL3. Meets the requirement according to IEC 61508 (2nd Ed. 2011) Certifi ed by TÜV Süd MPA 41xx automatic gas burners are suitable for all types of one-stage or modulating gas burners with and without ignition gas. The fl ame is monitored either by means of an ionisation input, gate input or both inputs for burners with two fl ame detector positions.

Example for connection

Atmospheric burner with ignition gas output. After the heat request and an adjustable delay, the ignition is switched on and V1 and Vz are opened. After the fl ame has been detected, the main gas fl ow V2 is opened. Fan burner, direct ignition of the main gas fl ame. After the heat request, the fan is switched on, and the air pressure is checked by the pressure switch. After the pre-aeration time has lapsed, the ignition is switched on, and the two valves V1 and V2 are opened together.

The program sequence and times can be modifi ed on the mounted display (MPA 4112/MPA 4122) to match each application. A laptop or PC is not required for the modifi cation. The automatic burners are protected by passwords against unauthorised access.

Display modes Operation display • Display of the current operating state • Display of the program state • Display of bus address Info display • Display of fl ame quality • Display of resettable counters for start-up, operating hours and operating cycles

Error display Display of the error memory • Automatic activation of error messages • Additional information about faults • Query of the last ten faults