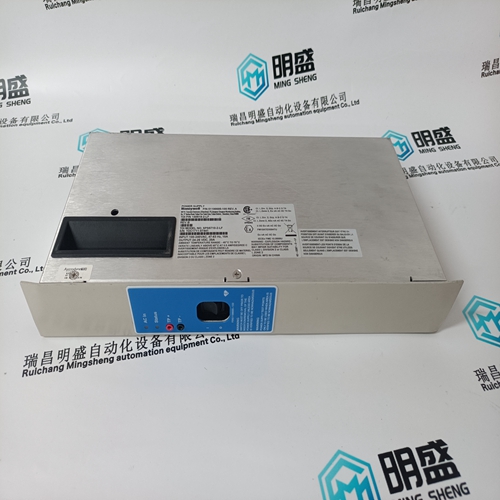

Home > Product > Servo control system > HIMA F7126 Power supply module

HIMA F7126 Power supply module

- Product ID: F7126

- Brand: HIMA

- Place of origin: Germany

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:HIMAF7126Power supply module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

HIMA F7126 Power supply module

Accessories Flame detector FLW 10 IR IR fl ame detector for connection to ionisation input. Suitable for intermittent operation. FLW 20 UV UV fl ame detector for connection to ionisation input. Suitable for intermittent operation. UV 41 (HE)/UV 42 UV fl ame detector for high mechanical load; metallic version. Suitable for intermittent operation. With shutter module suitable for continuous operation FLW 41 I Flame safeguard module for ionisation fl ame monitoring. The FLW 41I is connected to the second fl ame guard input of the MPA 41xx. When equipped with an extension module, for example EM 2/4, suitable for continuous operation.

Parameter display • Password-protected functional levels for service and OEM parameter settings • Setting of important parameters such as: Pre-purge time Safety time for startup phase Post-purge time Behaviour after fl ame lift-off Operating modes of V1 and V2 Continuous or intermittent operation MPA 41 extension module EM2/4 Additional circuit board and connector set for Profi bus DP and Modbus communication. MPA 41 extension module EM2/6 Additional circuit board for Profi bus DP and Modbus communication. PWM output for open loop control of DC fans, voltage-/current output also program state related relay outputs. Parameter setting and service MPA 41 parameterisation and service box Universal support for checking devices in the fi eld; for producing small and medium series. MPA Vision Box In addition to MPA41 parameterisation and service box for setting parameters via a PC/laptop.

MPA 41xx System description

The automatic gas burner control systems MPA 41xx are suitable for intermittent or continuous operation of gas burners with or without fan. The system parameters may be set on the integrated display (MPA 4112/ MPA 4122) and/or using the DUNGS VisionBox. The flame is either monitored using an ionisation electrode, a DUNGS FLWXX flame detector or DUNGS UV 41 flame detector connected to the ionisation electrode input or over a second flame detector input for a flame detector with potential-free two-way contact or by means of the DUNGS UV 42 flame detector. Both flame detector inputs may be used individually or combined. The MPA 41xx parameterisation and service box is available for the production of small series and for checking the system when service is required. For operation in burner networks, a Profibus/Modbus communication over the extension module EM-2/4 or EM 2/6 is possible.Riks of fatal electric shocks! You must interrupt the power supply before removing the hood. After having removed the hood, you might get in contact with the electrical connections in the terminal socket.

Do not remove the jumper between terminals 1 and 2, which was mounted in the factory. It is required for the intended use of the automatic gas burner control system.