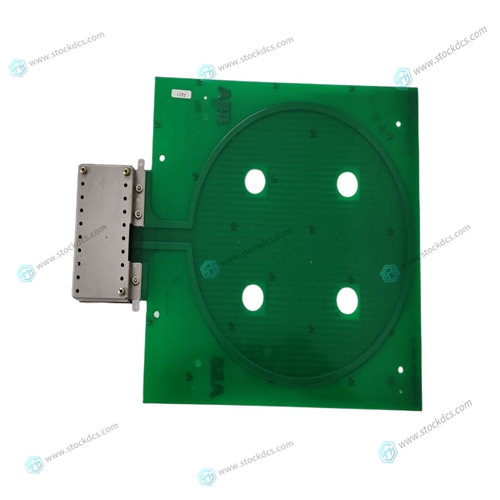

Home > Product > DCS control system > ABB UFC789AE101 3BHE014023R0101 Output expansion card

ABB UFC789AE101 3BHE014023R0101 Output expansion card

- Product ID: UFC789AE101 3BHE014023R0101

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ABBUFC789AE1013BHE014023R0101Output expansion card

- Get the latest price:Click to consult

ABB UFC789AE101 3BHE014023R0101 Output expansion card

The following table is to be seen as a “First Aid” box. There can be a large number of different reasons for a fault, depending on the particular conditions in your system. The fault causes described below are mostly those which directly influence the motor. Peculiarities which show up in the control loop behaviour can usually be traced back to an error in the parameterization of the servo amplifier. The documentation for the servo amplifier and the operator software provides information on these matters. For multi-axis systems there may be further hidden reasons for faults. Our applications department can give you further help with your problems.

Possible cause

Measures to remove the cause of the fault Motor doesn’t rotate — servo amplifier not enabled — Break in setpoint lead — Motor phases in wrong sequence — Brake not released — Drive is mechanically blocked — Supply ENABLE signal — Check setpoint lead — Correct the phase sequence — Check brake controls — Check mechanism Motor runs away — Motor phases in wrong sequence — ROD cable faulty or not properly plugged in (for option -IL- ) — Correct the phase sequence — Check ROD/SSI cable Motor oscillates — Break in the shielding of the resolver cable — amplifier gain to high — Replace resolver cable — use motor default values Error message: brake — Short-circuit in the supply voltage lead to the motor holding brake — Faulty motor holding brake — Remove the short-circuit — Replace motor

Error message:

output stage fault — Motor cable has short-circuit or earth short — Motor has short-circuit or earth short — Replace cable — Replace motor Error message: resolver — Resolver connector is not properly plugged in — Break in resolver cable, cable crushed or similar — Check connector — Check cables Error message: motor temperature — Motor thermostat has switched — Loose resolver connector or break in resolver cable — Wait until the motor has cooled down. Then investigate why the motor becomes so hot. — Check connector, replace resolver cable if necessary Brake does not grip — Required holding torque too high — Brake faulty — Motor shaft axially overloaded — Check the dimensioning — Replace motor — Check the axial load, reduce it. Replace motor, since the bearings have been damaged

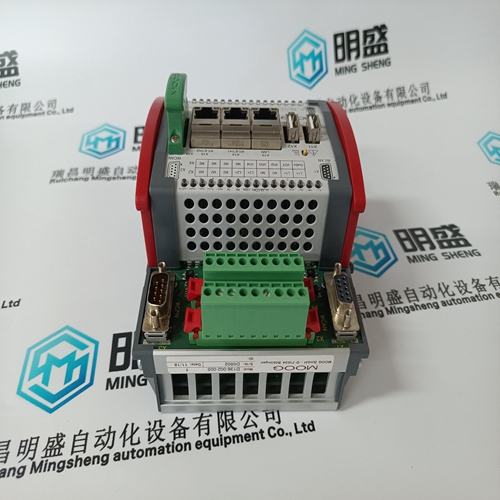

Our products

A company specializes in the sales of module spare parts of global famous brands (DCS system) (robot system) (large servo control system). The company's products include distributed control system (DCS), programmable controller (PLC), MOTOROLA MVME industrial module, industrial control communication converter (Anybus), remote output/input module (RTU), industrial computer (IPC), industrial low screen screen (IPC) HMI SCSI (50, 68, 80Pin) AnyBus (Gateway) has become a global sales enterprise of industrial automation spare parts and components

Payment method and delivery

Shipment: EMS,DHL,UPS & FEDEX

Payment: T/T or Western Union