Home > Product > DCS control system > ABB 07LE90 Channel isolation module

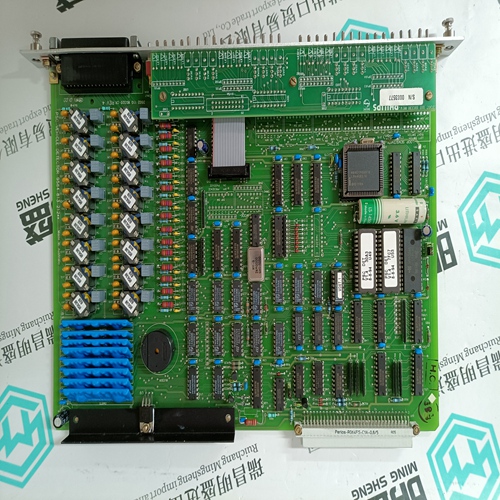

ABB 07LE90 Channel isolation module

- Product ID: 07LE90

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ABB07LE90Channel isolation module

- Get the latest price:Click to consult

ABB 07LE90 Channel isolation module

PRINCIPLE OF OPERATION A. Normal regulation. The internal monitor orifice operates like a standard one-piece orifice, performing normal regulation. B. Normal lock-up. The regulator is free to lock-up in the usual manner. The O-ring seal prevents gas from leaking past the orifice exterior into the downstream or low pressure side of the valve body. C. Dual monitor operation - internal foreign material failure. If the regulator fails to lock-up for any reason, the internal monitor orifice automatically goes into operation. Outlet pressure increases slightly, causing the valve seat to push against the inner or sliding part of the orifice gradually compressing the monitor spring and closing the secondary or monitor orifice on the inlet side of the sliding orifices. At this point, the B-838-IM functions as a monitor regulator.

For example

assume a weld bead is caught between the orifice and the valve seat while the regulator is in high-flow operation. If the flow reduces, the valve tries to close but can't due to the foreign matter. The outlet pressure increases approximately 2" w.c. above the original set point which starts to close the secondary monitor orifice. If the gas demand is decreased, the monitor orifice will partially close and become the new operating orifice. The new orifice will function as a monitor regulator and keep the outlet pressure approximately 3" above the set pressure on inches water column, or .8 PSIG when set for PSIG outlet. If the flow becomes further reduced to no-flow, then the sliding orifice (or orifices) close against the secondary rubber seat providing a complete no-gas flow with a total outlet pressure build up of only 6" w.c. above the original set point.

VENT LINES FOR REGULATORS

When constructing vent lines to be attached to regulators installed indoors, follow a few basic rules: a. Never use pipe sizes smaller than the vent size; smaller pipe sizes restrict the gas flow. If a long gas run must be used, Itron advises increasing the pipe one nominal size every ten feet to keep the flow restriction as low as possible. b. Keep the vent line length as short as possible to minimize the restriction and reduce the vent's tendency to cause regulator pulsation. c. Support the vent pipe to eliminate strain on the regulator diaphragm case. d. Always point outdoor vent pipes in the downward position to reduce the possibility of rain, snow, sleet, and other moisture entering the pipe. Install a bug screen in the end of the pipe. e. Do not locate the vent line terminus near windows, fans, or other ventilation equipment. See the installation instructions furnished with the regulator. f. Adhere to all applicable codes and regulations. g. If your vent pipe causes regulator pulsation, consult your sales representative or manufacturer. h. Itron strongly recommends running a separate vent line for each regulator. Headers with various installed devices can cause regulator malfunction.

Application industry

The products can be used in the following industries: power plant, paper making, steel, mining, rubber, water supply, cement, chemical industry, glass, printing

Textile, machinery, plastics, coatings, medicine, hospitals, food, hotels, scientific research institutions

Do you want to know about our products?

We have a large amount of inventory and high quality, out of production control system components, DCS system accessories, robot system accessories, large servo system spare parts. PLC module, DCS module, CPU module, IO module, DO module, AI module, DI module, network communication module, Ethernet module, motion control module, analog input module, analog output module, digital input module, digital output module, redundancy module, power module, relay output module, relay input module, processor module and other major brands.