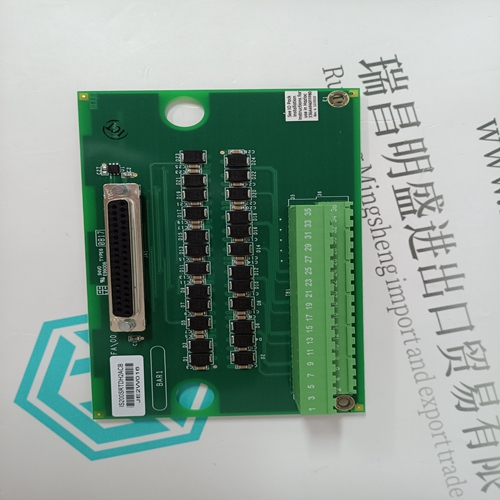

Home > Product > DCS control system > ABB 086362-001 Channel isolation card

ABB 086362-001 Channel isolation card

- Product ID: 086362-001

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ABB086362-001Channel isolation card

- Get the latest price:Click to consult

ABB 086362-001 Channel isolation card

a. Remove all shipping plugs from the regulator inlet, outlet, and vent before installation.

b. Verify the piping interior and regulator inlet and outlet are clean and free of dirt, pipe dope, and other debris. Dirt and other foreign materials entering the regulator can cause a loss of pressure control.

c. Apply pipe joint sealant to the male pipe threads. Do not use pipe joint material on the regulator's female threads. Joint sealant could become lodged in the regulator and cause a loss of pressure control.

d. Gas must flow through the regulator's valve body in the direction cast on the regulator body. Gas flowing in the wrong direction can overpressure and cause damage to the regulator.

e. The diaphragm casing can be mounted in any position relative to the body through a full 360° angle at 90° increments.

When the regulator is installed OUTDOORS

the vent must always be positioned so that rain, snow, moisture or foreign particles cannot enter the vent opening. Itron recommends positioning the vent downward to avoid entry of water or other matter which could interfere with the proper operation of the regulator. The vent should be located away from building eaves, window openings, building air intakes and above the expected snow level at the site. The vent opening should be inspected periodically to insure it does not become blocked by foreign material as outlined in DOT PHMSA-RSPA-2004-19856. g. When the regulator is installed INDOORS, the vent must be piped to the outside atmosphere using the shortest length of pipe, the fewest possible pipe elbows, and a pipe diameter as large as the vent size or larger. USING VENT PIPE SMALLER THAN THE VENT CONNECTION LIMITS THE REGULATOR’S INTERNAL RELIEF VALVE CAPACITY. The outlet end of the pipe must be protected from moisture and the entrance of foreign particles. The regulator should be specified by the user with the size vent and pipe threads desired to make the vent pipe connection.

START-UP AND ADJUSTMENT

The seal caps for the main diaphragm cases must always be installed and wrench tight before introducing gas flow to the regulator and for as long as gas pressure is present in the regulator. a. Mount a pressure gauge downstream of the regulator to monitor the downstream pressure. b. With the downstream pressure valve closed, slowly open the inlet valve. The outlet pressure should rise to slightly more than the set-point. Verify there are no leaks and all connections are tight. c. The regulator was pre-set at the factory to match order specifications. If regulator readjustments are necessary, the adjustment is made to the springs only. While the regulator is under steady flow conditions of 500 cfh or more, remove the regulator seal caps. Caution Never remove or loosen main diaphragm case seal caps while gas is present, under pressure, in the regulator.

Application industry

The products can be used in the following industries: power plant, paper making, steel, mining, rubber, water supply, cement, chemical industry, glass, printing

Textile, machinery, plastics, coatings, medicine, hospitals, food, hotels, scientific research institutions

Do you want to know about our products?

We have a large amount of inventory and high quality, out of production control system components, DCS system accessories, robot system accessories, large servo system spare parts. PLC module, DCS module, CPU module, IO module, DO module, AI module, DI module, network communication module, Ethernet module, motion control module, analog input module, analog output module, digital input module, digital output module, redundancy module, power module, relay output module, relay input module, processor module and other major brands.