Home > Product > DCS control system > ABB EI802F 3BDH000016R1 Overspeed tachometer clamp

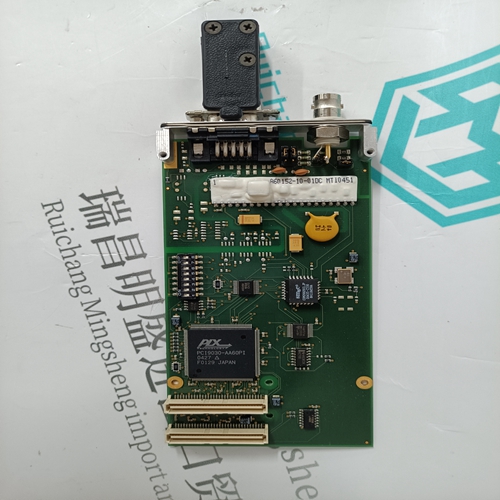

ABB EI802F 3BDH000016R1 Overspeed tachometer clamp

- Product ID: EI802F 3BDH000016R1

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ABBEI802F3BDH000016R1Overspeed tachometer clamp

- Get the latest price:Click to consult

ABB EI802F 3BDH000016R1 Overspeed tachometer clamp

• Do not bend the metal mounting strap. This may cause improper mounting of the fixation units of the sensor rails.

• Protect the pipe contact side of the transducer. Scratches or other damages may have a negative impact on its proper functioning. • Before fitting the transducer to the transducer knob in the sensor rail, check the connection groove of the transducer cover for damages or dirt. Clean or replace when dirty or damaged.

• Check sensor cabling with regular intervals for damages and wear as this may cause improper functioning. Replace when necessary.

• Check presence of sufficient grease on the transducer pipe contact side in case of acoustic signal failure.

• Check the sensor rail sliding area regularly for dirt or other pollution or excess coupling fat, that may cause improper functioning.

• Excess of coupling fat may be removed from the sensor rails and transducers with a drypiece of cloth. Coupling fat on the converter housing may be removed using soapy water.

Find location and determine data

Inlet, outlet and recommended mounting area To perform an accurate flow measurement preferably mount the sensor rail at least 10 DN downstream of a flow disturbance like elbows, valves, headers or pumps. Follow the given installation recommendations.Do not start to mount the rails yet! Step 1 is only meant to find a suitable location for a measurement. The installation itself will be done in Step 3.

INSTALLATION FOR FLOW MEASUREMENT

• In order to comply with the EMC directive 2004/108/EC, I/O cables that provide a galvanic connection to the UFC 300 P should have a maximum total length of 3 meter.

• When not used, put the connector covers of the connectors on the bottom side of the converter in place. This to prevent improper functioning caused by dust/dirt.

• When the sensor cables are connected while the converter is positioned on a flat surface, turn the handle fully backwards (towards the housing) in order to prevent excess stress on the sensor cables.

• In order to keep the battery at an optimum condition the battery should be charged at least once every 6 months.

• If the main battery is empty for a period longer than one year, the backup battery of the real time clock may run empty

Application industry

The products can be used in the following industries: power plant, paper making, steel, mining, rubber, water supply, cement, chemical industry, glass, printing

Textile, machinery, plastics, coatings, medicine, hospitals, food, hotels, scientific research institutions

Do you want to know about our products?

We have a large amount of inventory and high quality, out of production control system components, DCS system accessories, robot system accessories, large servo system spare parts. PLC module, DCS module, CPU module, IO module, DO module, AI module, DI module, network communication module, Ethernet module, motion control module, analog input module, analog output module, digital input module, digital output module, redundancy module, power module, relay output module, relay input module, processor module and other major brands.