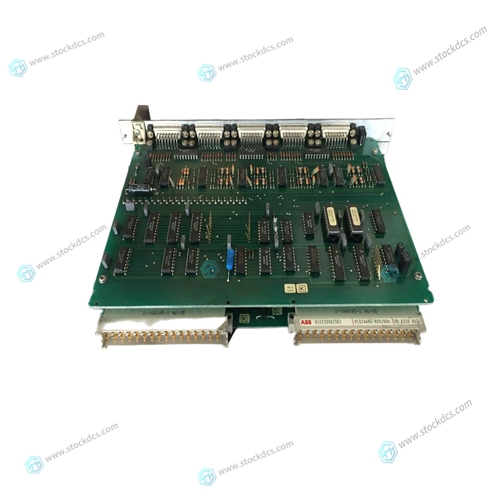

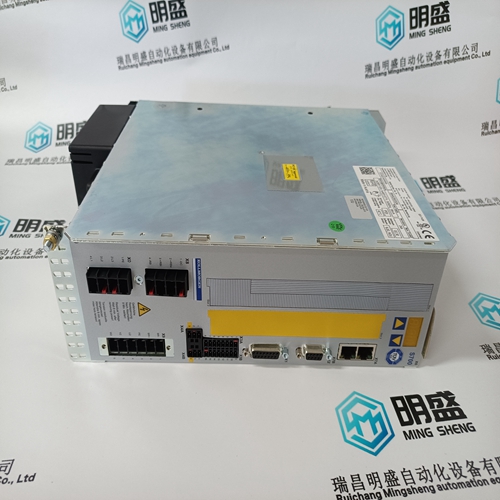

Home > Product > DCS control system > ABB HIEE300025R2 Thermal resistance module

ABB HIEE300025R2 Thermal resistance module

- Product ID: HIEE300025R2

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ABBHIEE300025R2Thermal resistance module

- Get the latest price:Click to consult

ABB HIEE300025R2 Thermal resistance module

The actuators are equipped with an oil pump and must be driven either by the turbine or other means, such as an electric motor. Factory adjustments allow the actuators to be calibrated over given ranges of input signal consistent with the type of controls in which they are used. OPTIONAL EQUIPMENT The standard model requires a mechanical drive, however a unit is available which requires only a customer-supplied hydraulic pressure source. Class I, Division 2, Groups B, C, and D UL listed actuators are available. NOTE: Unless otherwise specified, TG-13E and - 17E actuators are calibrated for vertical operation. When used in a horizontal application these actuators will have approximately a 5° to 6° shift in terminal shaft calibration. Breather cap location must also be changed.

Plunger Movement

The pilot valve is actuated hydraulically by varying the oil flow from a nozzle. The flapper, which is controlled by the transducer, varies the flow of oil from the nozzle causing a pressure change above the differential power land, forcing it to move. Oil is then directed to or from the power piston, changing the restoring spring forces until the pilot valve is returned to its null position.Oil Self-contained sump; SAE 10 to 50 is recommended with a viscosity of 100 to 300 to SUS, depending on operating temperature. See Woodward oil manual 25071 for recommended oils.

Terminal Blocks

For wiring between an I/O module and field equipment, a signal cable interface adapter or a pressure clamp terminal block is available. MIL cables provided by the user may be used with a connector cover for MIL cable. For a signal interface adapter, dedicated signal cable is used to connect with terminal board or relay board. There is option to prevent wrong type I/O module insertion. Option codes for this mechanism must be specified for I/O module and signal cables respectively. The I/O module and the signal interface adapter is the set purchase. A pressure clamp terminal can be directly wired to field equipment. A signal cable interface adapter can be wired to field equipment via a terminal board. There are two types of pressure clamp terminal blocks: a single configuration type and a dual-redundant configuration type. An I/O module can be made dual redundant on the terminal block. An MIL cable can be directly connected to an I/O module without a terminal block. This cable is provided to customers by option. To prevent it from being disconnected from the I/O module, cable connector covers (SCCC01 and SCCC02) are available for the use with the MIL cable.

Application industry

The products can be used in the following industries: power plant, paper making, steel, mining, rubber, water supply, cement, chemical industry, glass, printing

Textile, machinery, plastics, coatings, medicine, hospitals, food, hotels, scientific research institutions

Do you want to know about our products?

We have a large amount of inventory and high quality, out of production control system components, DCS system accessories, robot system accessories, large servo system spare parts. PLC module, DCS module, CPU module, IO module, DO module, AI module, DI module, network communication module, Ethernet module, motion control module, analog input module, analog output module, digital input module, digital output module, redundancy module, power module, relay output module, relay input module, processor module and other major brands.