Home > Product > DCS control system > ABB PFBK 165 3BSE000470R1 Sequence control module

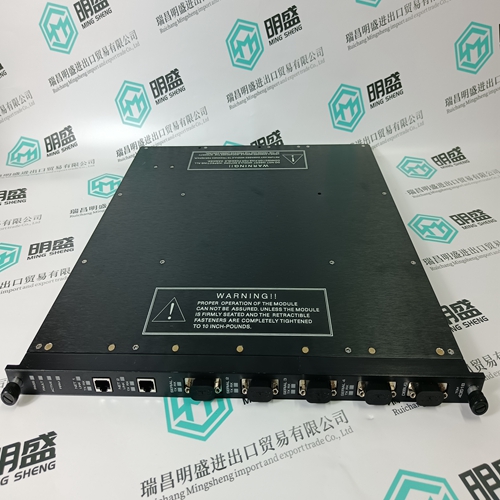

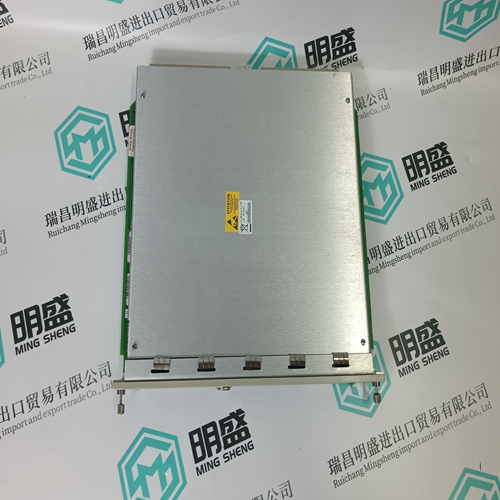

ABB PFBK 165 3BSE000470R1 Sequence control module

- Product ID: PFBK 165 3BSE000470R1

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:ABBPFBK 1653BSE000470R1Sequence control module

- Get the latest price:Click to consult

ABB PFBK 165 3BSE000470R1 Sequence control module

Terminal Board is Connected The SDV541 digital output module can respectively handle a maximum of 0.2 A load currents per channel. However, this can cause the generation of a voltage drop due to connected cable and adapter resistance components, etc. Therefore, it is necessary to take account of the limitations on the magnitude of load current and connected cable length as given below. In case of short circuits detection is enabled, the possible cable length may be limited The voltage drop from the external power supply (Vp) to the output channel load is a total voltage drop of ∆V1 in the power line, ∆V2 in the signal line and ∆V3 in the circuit inside Digital Output Module.

The KBWC Series is a comprehensive

line of motor speed controls for air-moving applications that utilize Shaded Pole, Permanent Split Capacitor (PSC), and AC/DC motors. These economical speed controls are designed to replace obsolete, tapped winding, or reactive methods of speed control. The full-wave phase control circuitry minimizes power loss, thereby reducing energy requirements. The controls provide infinitely variable speed adjustment which allows the end-user to select the desired level of air volume. These models cover a wide range of current ratings (2.5 - 15 Amps AC) and voltage ratings (115, 230, 277 Volts AC). Important features, such as RFI Filter, Minimum Speed Trimpot, and built-in On/Off Line Switch are standard. These speed controls are available as bulk packaged or in distributor type packaging with accessories such as: knob, dial plate, mounting hardware, instructions, and individual carton. All models are designed to be mounted into a standard 2” X 4” electrical wall box.

APPLICATION NOTES

1. Radio Frequency Interference (RFI): All solid-state speed controls generate annoying radio noise on the AM band. KB speed controls contain, as standard, a high-gain RFI suppression filter which significantly reduces this interference. 2. Low End Set Point (Minimum speed): All 115 Volt input speed controls are factory set to 65 Volts AC output (±3 Volts), as standard. All 230 Volt input speed controls are factory set to 120 Volts AC output (±6 Volts), as standard. All controls are factory calibrated using an average responding AC voltmeter. Custom voltage settings are available. 3. Motor Suitability: Motors must be loaded to near full capacity with the appropriate fan blade in order to achieve proper speed control. Generally, motor suitability is established by determining motor speed as a function of applied voltage. A motor is determined as suitable if it changes speed linearly over a wide range of voltage. It is required that all motors contain a built-in thermal overload protector when used with solid-state speed controls.

Application industry

The products can be used in the following industries: power plant, paper making, steel, mining, rubber, water supply, cement, chemical industry, glass, printing

Textile, machinery, plastics, coatings, medicine, hospitals, food, hotels, scientific research institutions

Do you want to know about our products?

We have a large amount of inventory and high quality, out of production control system components, DCS system accessories, robot system accessories, large servo system spare parts. PLC module, DCS module, CPU module, IO module, DO module, AI module, DI module, network communication module, Ethernet module, motion control module, analog input module, analog output module, digital input module, digital output module, redundancy module, power module, relay output module, relay input module, processor module and other major brands.