Home > Product > DCS control system > ABB 3HNA001625-001 PROCESS I/O

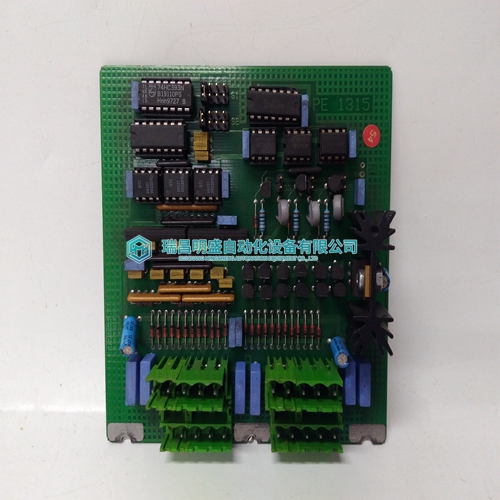

ABB 3HNA001625-001 PROCESS I/O

- Product ID: 3HNA001625-001

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ABB3HNA001625-001PROCESS I/O

- Get the latest price:Click to consult

ABB 3HNA001625-001 PROCESS I/O

Wrap Teflon pipe tape around the threaded male portion of the fittings.

• Use new tape each time you make a connection.

• Wrap the tape so it will tighten into the threads when you screw in the fittings. Pointing the fitting towards yourself, make the tape wrap in a clockwise (CW) direction.

• Wrap tightly and make two (2) layers of tape around the fittings’ threads.

Screw in fittings carefully by hand, “hand-tight” only.

Ensure that the unit’s water ports will not twist when the connections are tightened further. If the unit does not have a built-in hex bracket or water guard retrofit for the water ports, brace the ports with an open-end wrench.

Use a torque wrench to tighten fittings to 150 to 170 lb-in or 12.5 to 14.2 lb-ft range. (Metric equivalents: 1.73 kg-m to 1.96 kg-m and 16.9 N-m to 19.2 N-m.) Service centers and Manufacturing use calibrated 150 lb. wrenches.

Maintenance & Cleaning

The GHW-25 / GHW-50 Genesis generator is designed and built to require a minimum of cleaning and maintenance. It is recommended however, that the unit be wiped down on the outside with a damp cloth to remove any build-up of dust and dirt. ! To minimize the risk of accidental shock, turn off the AC mains breaker before wiping off the unit and around the rear panel connections.

System Check

Before the GHW-25 / GHW-50 Genesis generator can be used, it is imperative that the following procedure be followed to ensure optimal and safe operation. 1. If you've purchased your generator with the optional solenoid valve kit (as mentioned in Section 2.8.3), make sure the solenoid plug is attached to the solenoid connector on the rear panel marked “SOLENOID.” 2. The water hoses are securely connected to the water connectors on the rear panel. (See section 2.10 for more information on the connectors.) 3. The external interlock plug is inserted in the interlock connector on the rear panel marked “INTERLOCK.” AC Power will not engage until this interlock is defeated (plugged). (See section 2.7 for more information about the safety interlocks.)

Company introduction

Temporal Ming sheng automation equipment co., LTD. Was established in April 02, 2021, registered jiujiang ruichang city in jiangxi province, east yi road no. 23 lake farmers 401 mall, the legal representative person Zhou Zuochen.

[Main Products]

Main products: PLC and DCS system spare parts modules of world famous brands

①Allen-Bradley 1756、1746、1747、1771、1785

②Schneider 140 Series PLC module

③General electric GE

IC693 IC697 IC698 Series PLC module

DS200 DS3800 DS215 IS200 IS215 IS220 Series gas turbine module

VMIVME Control module of series

④Bently:3500 series cards 3500/22M、3500/15、3500/92 And other products

⑤ICS TRIPLEX

⑥ABB Robots. FANUC Robots、YASKAWA Robots、KUKA Robots、Mitsubishi Robots、OTC Robots、Panasonic Robots、MOTOMAN Robots。

⑦EMERSON:Spare parts for OVATION system, WDPF system and MAX1000 system.

⑧ Invensys Foxboro: I/A Series system, FBM (field input/output module) sequential control, ladder logic control, accident recall processing, digital analog conversion, input/output signal processing, data communication and processing, etc. Invensys Triconex: redundant fault-tolerant control system, Zui modern fault-tolerant controller based on triple module redundancy (TMR) structure.

⑨Woodward:505 series governor 9907-164 And other products

⑩Bosch Rexroth:Indramat,I/O module,PLC CPU,Motors, drives and other products.

◆Motorola:MVME 162、MVME 167、MVME1772、MVME177and other products.