Home > Product > PLC programmable module > GU-D08 80173-109-01 Redundant module

GU-D08 80173-109-01 Redundant module

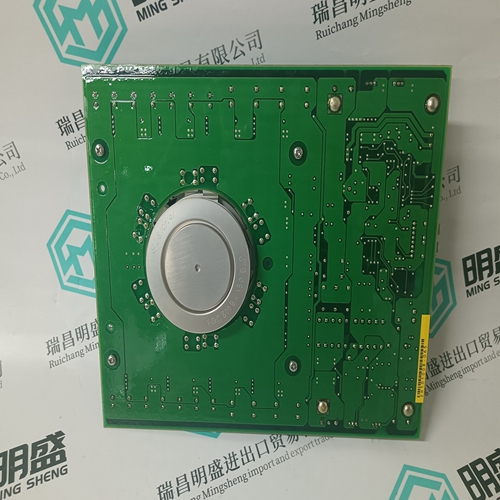

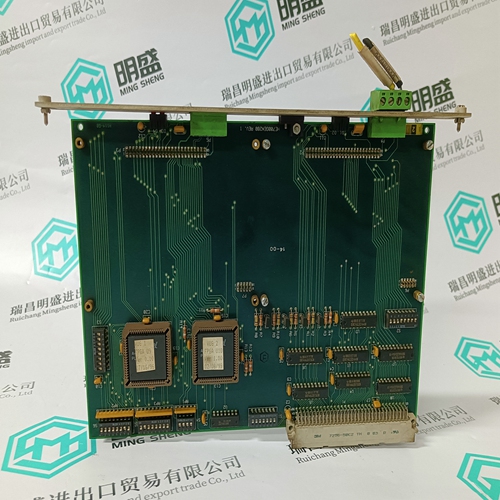

- Product ID: GU-D08 80173-109-01

- Brand: Mitsubishi

- Place of origin: JAPAN

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:GU-D08 80173-109-01Redundant moduleMITSUBISHI

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

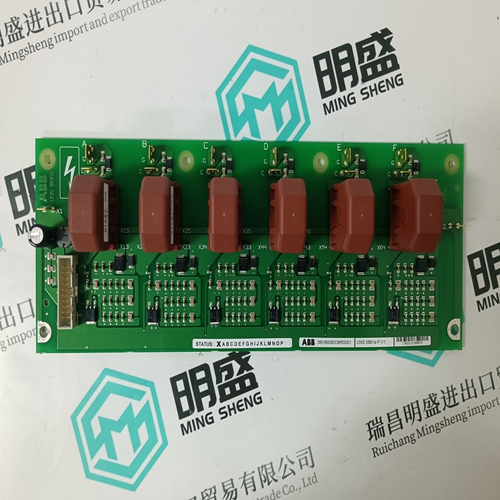

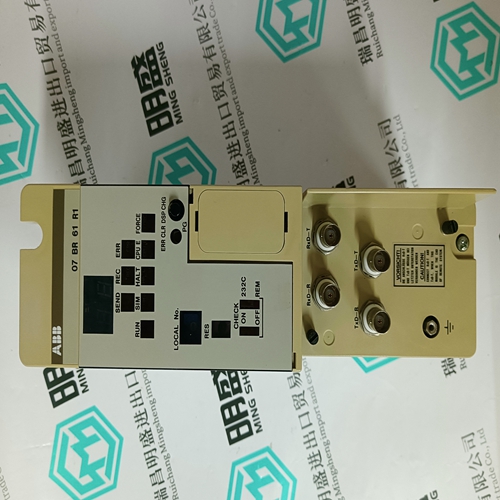

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

GU-D08 80173-109-01 Redundant module

Multiple options are available for replacing existing control processors with the FCP280. A fault-tolerant FCP280 may replace a fault-tolerant FCP270 or ZCP270. It may import the CP database from the CP270 it is replacing, for compatibility and minimal configuration time. The FCP280 provides an increase in performance and block processing capacity over the CP270s. When replacing the FCP270s with the FCP280, you do not need the FEM100 hardware. For ease of replacement, the fault-tolerant or non-fault-tolerant FCP280 in the standard baseplate has the same dimensions as the fault-tolerant or non-fault-tolerant FCP270 in its baseplate. The dual cable baseplate has larger dimensions than the standard baseplate. Cabling the 100 Series FBMs or Migration products to an FCP280 baseplate consists of extending the remote 268 Kbps fieldbus between enclosures. This is accomplished using termination cable assemblies (TCAs) and Fieldbus Isolators (FBIs) to provide connections between primary and extended fieldbus segments. The optional FBI200 can extend the 2 Mbps HDLC fieldbus between 200 Series FBMs from 60 m (198 ft) up to 305 m (1000 ft). As well, for standard FCP280 baseplates, it can extend the 268 Kbps HDLC fieldbus between 100 Series FBMs from 60 m (198 ft) in a mixed 100 & 200 Series FBMs configuration (or 300 m (1,000 ft) in an exclusive 100 Series FBMs configuration) up to 1830 m (6,000 ft). As with earlier generations of control processors, up to 128 100 Series FBMs (including expansion modules) attach to standard baseplate Fieldbus ports through Fieldbus Isolators (with a maximum of 64 100 Series FBMs per port). Up to 24 100 Series FBMs, excluding expansion modules, can connect to each isolator. However, the expansion modules are considered 100 Series FBMs in this “128 100 Series FBMs” maximum discussed in this PSS. Available upgrade scenarios are available in Field Control Processor 280 (FCP280) User’s Guide (B0700FW).

FBI200 Fieldbus Isolator/Filter

The FBI200 Fieldbus Isolator/Filter extends the length of the 268 Kbps module Fieldbus from the FCP280 to 100 Series FBMs and similar competitive migration modules up to 1,830 m (6,000 ft) over a twinaxial Fieldbus cable. See Typical FCP280 Network Configuration with Mixed 100 Series and 200 Series FBM Functionality (Simplified), page 6. It can also extend the 2 Mbps HDLC fieldbus to 200 Series FBMs up to 305 m (1,000 ft). For more information on the FBI200, see FBI200 Fieldbus Isolator/Filter (PSS 41H2FBI200). Firmware Upgrades While On-Line For fault-tolerant FCP280 modules, on-line image upgrade (OLUG) replaces the executable image (operating system) of a running FCP280 with a newer image. The enhanced on-line image upgrade (EOLUG) improves on this process by upgrading the FCP280 modules without having to shut down the equipment being controlled by the FCP280. This form of upgrade helps prevent any significant bumps to the local control process, removes the initialization of sequence logic and decreases the Object Manager reconnection time. Time Synchronization, SOE, TDR/TDA The Foxboro DCS System supports time synchronization using either an externally maintained optional source of Universal Coordinated Time (UTC) from GPS satellites or an internal source using proprietary software. FCP280s that receive time updates via the external time source synchronize their FBMs to 1 ms. For more information on time synchronization, see Time Synchronization Overview (PSS 41S-1TIME). Time stamping is used for alarm messages, values sent to the historian, the Foxboro DCS Sequence Of Events (SOE) and Transient Data Recorder (TDR), and Transient Data Analyzer (TDA) features. SOE data are discrete points that are time stamped at the FBM, optionally to 1 ms, and sent to the workstation on a change basis. TDR/TDA data are analog or digital points that are time stamped at the FBM and sent to the workstation every 10 ms. These features are supported by client software in the workstation. For information on this new software, see Field Control Processor 280 (FCP280) Integrated Control Software (PSS 41S-3FCPICS).