Home > Product > DCS control system > ABB YXU168E Switch input module

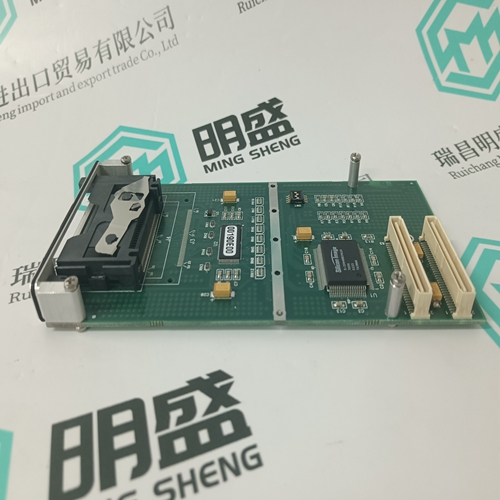

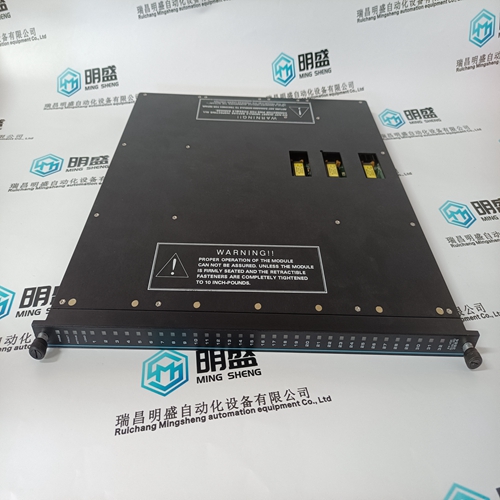

ABB YXU168E Switch input module

- Product ID: YXU168E

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ABBYXU168ESwitch input module

- Get the latest price:Click to consult

ABB YXU168E Switch input module

These faults can only be diagnosed using an external control device such as the ENI Monitor. When the system fault occurs a SYSTEM FAULT LED will illuminate on the front panel, use the RFV and the RPS command (See section 3.2.3) on the ENI monitor to determine the fault. Using the equal sign (=) after the RFV command will show the fault in words instead of a numerical value. This way of diagnosing a fault is only available if the unit has a fully functional front panel and the Analog Remote Interface is connected to a terminal to use the ENI Monitor. If the unit has a blank front panel, it must be connected to a terminal for any fault to be noticed. Otherwise, if and when a system fault occurs, only the SYSTEM FAULT LED will illuminate. Interlock status is shown on the front panel if the unit is open. “INLK OPEN” will be displayed on the STATUS line.

Analog Remote Interface Faults

If the unit is connected to a controller, such as ENI’s UTF-10, two more faults can be detected. One is an indicator driven (also known as a “Hard Fault”) and the other appears on the display (also known as a “Soft Fault”). 4.3.1 RF Overheat (Hard Fault) This fault occurs when the RF temperature is above the limit. The RF OVERHEAT lamp will light up on the front panel of the test fixture. 4.3.2 MAX POWER (Soft Fault) This fault occurs when the maximum power limit has been reached. The message will appear on the digital readout of the test fixture

Disclaimer and Copyright

The contents, images and graphics contained in this document are protected by copyright. In addition to the copyright, logos, fonts, company and product names can also be protected by brand law or trademark law. The use of text, extracts or graphics requires the permission of the publisher or rights holder. We have checked the contents of this document. Since errors cannot be ruled out entirely, we do not accept liability for mistakes which may have occurred. Notification of any mistake or suggestions for improvements will be gratefully received and any necessary correction will be included in subsequent editions.

Company introduction

Temporal Ming sheng automation equipment co., LTD. Was established in April 02, 2021, registered jiujiang ruichang city in jiangxi province, east yi road no. 23 lake farmers 401 mall, the legal representative person Zhou Zuochen.

[Main Products]

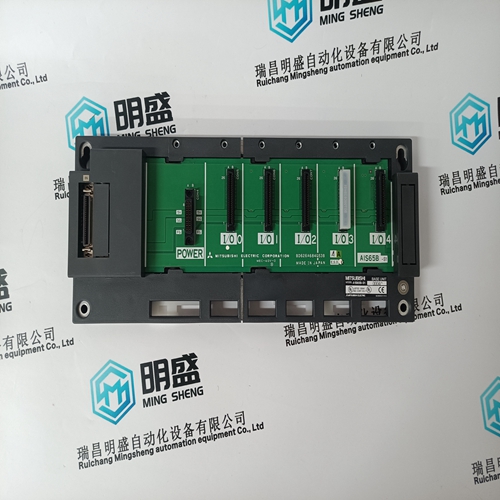

Main products: PLC and DCS system spare parts modules of world famous brands

①Allen-Bradley 1756、1746、1747、1771、1785

②Schneider 140 Series PLC module

③General electric GE

IC693 IC697 IC698 Series PLC module

DS200 DS3800 DS215 IS200 IS215 IS220 Series gas turbine module

VMIVME Control module of series

④Bently:3500 series cards 3500/22M、3500/15、3500/92 And other products

⑤ICS TRIPLEX

⑥ABB Robots. FANUC Robots、YASKAWA Robots、KUKA Robots、Mitsubishi Robots、OTC Robots、Panasonic Robots、MOTOMAN Robots。

⑦EMERSON:Spare parts for OVATION system, WDPF system and MAX1000 system.

⑧ Invensys Foxboro: I/A Series system, FBM (field input/output module) sequential control, ladder logic control, accident recall processing, digital analog conversion, input/output signal processing, data communication and processing, etc. Invensys Triconex: redundant fault-tolerant control system, Zui modern fault-tolerant controller based on triple module redundancy (TMR) structure.

⑨Woodward:505 series governor 9907-164 And other products

⑩Bosch Rexroth:Indramat,I/O module,PLC CPU,Motors, drives and other products.

◆Motorola:MVME 162、MVME 167、MVME1772、MVME177and other products.