Home > Product > DCS control system > YASKAWA YPHT1012-1 Line interface module

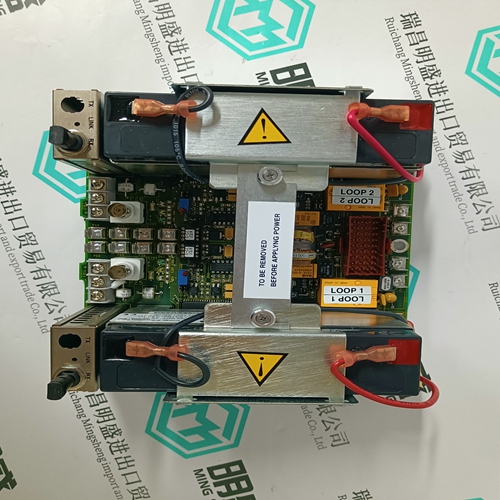

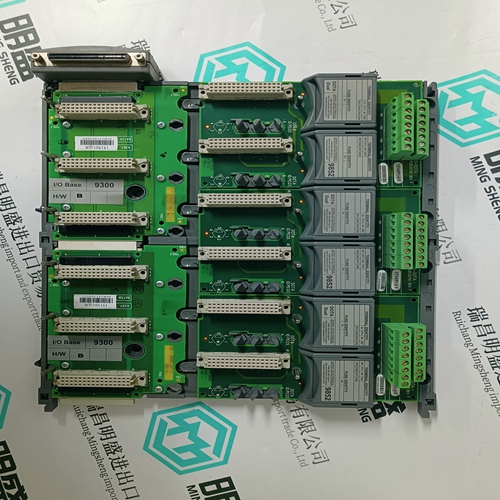

YASKAWA YPHT1012-1 Line interface module

- Product ID: YPHT1012-1

- Brand: YASKAWA

- Place of origin: JAPAN

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:YASKAWAYPHT1012-1Line interface module

- Get the latest price:Click to consult

YASKAWA YPHT1012-1 Line interface module

The product is fully protected provided that the connectors are correctly attached. Corrosion from the ambient atmosphere (condensation, liquids and gases) at the running surface of the output shaft seal is prevented. Contact between sharp edged or abrasive objects (cutting chips, splinters, metallic or minerals dusts etc) and the output shaft seal must be prevented. Permanent contact between the output shaft seal and a permanent liquid covering should also be prevented. A change in the operating temperature of a completely sealed actuator can lead to a pressure differential between the outside and the inside temperature of the actuator. This can cause any liquid covering the output shaft seal to be drawn into the housing which could cause corrosive damage. As a countermeasure, we recommend the use of an additional shaft seal (to be provided by the user) or the maintenance of a constant pressure inside the actuator. Please contact Harmonic Drive AG for further information.

Shutdown and Maintenance

In case of malfunctions or maintenance measures, or to shutdown the motors, proceed as follows: 1. Follow the instructions in the machine documentation. 2. Bring the actuator on the machine to a controlled standstill. 3. Turn off the power and the control voltage on the controller. 4. For motors with a fan unit; turn off the motor protection switch for the fan unit. 5. Turn off the mains switch of the machine. 6. Secure the machine against accidental movement and against unauthorised operation. 7. Wait for the discharge of electrical systems then disconnect all the electrical connections. 8. Secure the motor, and possibly the fan unit, before disassembly against falling or movement then pay attention to the mechanical connections.

Burns from hot surfaces with temperatures of over 100°C

Let the motors cool down before starting work. Cooling times of up to 140 minutes may be necessary. Wear protective gloves. Do not work on hot surfaces! Persons and property during maintenance and operation Never perform maintenance work on running machinery. Secure the system during maintenance against re-starting and unauthorised operat

Company introduction

Temporal Ming sheng automation equipment co., LTD. Was established in April 02, 2021, registered jiujiang ruichang city in jiangxi province, east yi road no. 23 lake farmers 401 mall, the legal representative person Zhou Zuochen.

[Main Products]

Main products: PLC and DCS system spare parts modules of world famous brands

①Allen-Bradley 1756、1746、1747、1771、1785

②Schneider 140 Series PLC module

③General electric GE

IC693 IC697 IC698 Series PLC module

DS200 DS3800 DS215 IS200 IS215 IS220 Series gas turbine module

VMIVME Control module of series

④Bently:3500 series cards 3500/22M、3500/15、3500/92 And other products

⑤ICS TRIPLEX

⑥ABB Robots. FANUC Robots、YASKAWA Robots、KUKA Robots、Mitsubishi Robots、OTC Robots、Panasonic Robots、MOTOMAN Robots。

⑦EMERSON:Spare parts for OVATION system, WDPF system and MAX1000 system.

⑧ Invensys Foxboro: I/A Series system, FBM (field input/output module) sequential control, ladder logic control, accident recall processing, digital analog conversion, input/output signal processing, data communication and processing, etc. Invensys Triconex: redundant fault-tolerant control system, Zui modern fault-tolerant controller based on triple module redundancy (TMR) structure.

⑨Woodward:505 series governor 9907-164 And other products

⑩Bosch Rexroth:Indramat,I/O module,PLC CPU,Motors, drives and other products.

◆Motorola:MVME 162、MVME 167、MVME1772、MVME177and other products.