Home > Product > DCS control system > YASKAWA YPHT31272-4E Power module

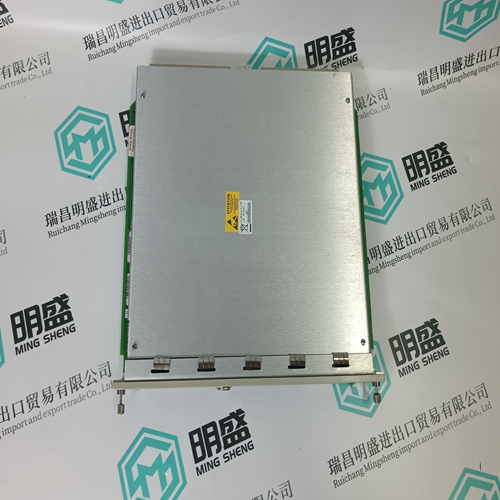

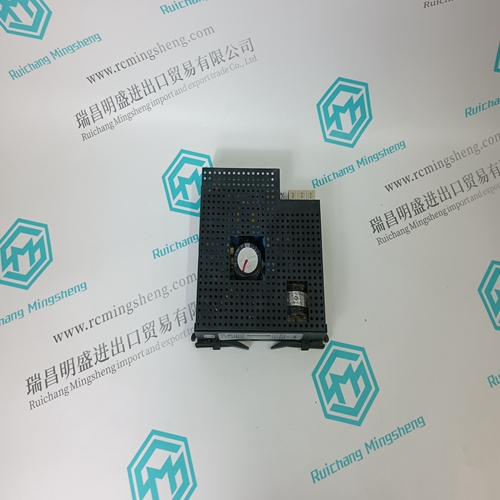

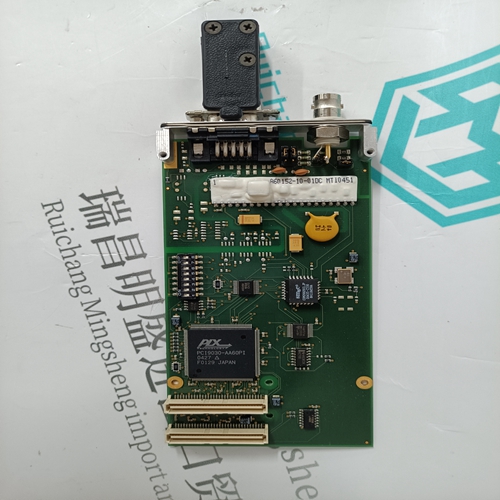

YASKAWA YPHT31272-4E Power module

- Product ID: YPHT31272-4E

- Brand: YASKAWA

- Place of origin: JAPAN

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:YASKAWAYPHT31272-4EPower module

- Get the latest price:Click to consult

YASKAWA YPHT31272-4E Power module

The 6SM27..107 series of synchronous servomotors is designed especially for drives for industrial robots, machine tools, textile and packing machinery and similar with high requirements for dynamics. The user is only permitted to operate the motors under the ambient conditions which are defined in this documentation. The 6SM27..107 series of motors is exclusively intended to be driven by servo amplifiers from the SERVOSTAR series under speed and / or torque control. The motors are installed as components in electrical apparatus or machines and can only be commissioned and put into operation as integral components of such apparatus or machines. The motors must never be connected directly to the mains supply. The thermal contact which is integrated in the motor windings must be observed and evaluated. The conformity of the servo system to the standards mentioned in the manufacturers declaration on page 6 is only guaranteed when the components (servo amplifier, motor, cables etc.) that are used have been supplied by us.

Design of the motors

Synchronous servomotors in the 6SM27..107 series are brushless DC motors for demanding servo applications. When combined with our digital servo amplifiers they are especially suited for positioning tasks in industrial robots, machine tools, transfer lines etc. With high requirements for dynamics and stability. The servomotors have permanent magnets in the rotor. The rare earth neodymium -iron-boron magnetic material is an important factor in making it possible to drive these motors in a highly dynamic fashion. A three-phase winding which is driven by the servo amplifier is integrated into the stator. The motor does not have any brushes since commutation is performed electronically by the servo amplifier

The temperature of the winding

is monitored by temperature sensors in the stator windings and is signalled via an electrically isolated contact (normally closed). A resolver is built into the motors as standard feedback element. The servo amplifiers in the SERVOSTAR series evaluate the resolver (hence rotor) position and supply sinusoidal currents to the motors. The motors can be delivered with or without a built-in holding brake. Retrofitting of the brake is not possible. The motors are enamelled in matt black (RAL 9005). This finish is not resistant against solvents (e.g. trichlorethylene, nitro-thinners, or similar).

Company introduction

Temporal Ming sheng automation equipment co., LTD. Was established in April 02, 2021, registered jiujiang ruichang city in jiangxi province, east yi road no. 23 lake farmers 401 mall, the legal representative person Zhou Zuochen.

[Main Products]

Main products: PLC and DCS system spare parts modules of world famous brands

①Allen-Bradley 1756、1746、1747、1771、1785

②Schneider 140 Series PLC module

③General electric GE

IC693 IC697 IC698 Series PLC module

DS200 DS3800 DS215 IS200 IS215 IS220 Series gas turbine module

VMIVME Control module of series

④Bently:3500 series cards 3500/22M、3500/15、3500/92 And other products

⑤ICS TRIPLEX

⑥ABB Robots. FANUC Robots、YASKAWA Robots、KUKA Robots、Mitsubishi Robots、OTC Robots、Panasonic Robots、MOTOMAN Robots。

⑦EMERSON:Spare parts for OVATION system, WDPF system and MAX1000 system.

⑧ Invensys Foxboro: I/A Series system, FBM (field input/output module) sequential control, ladder logic control, accident recall processing, digital analog conversion, input/output signal processing, data communication and processing, etc. Invensys Triconex: redundant fault-tolerant control system, Zui modern fault-tolerant controller based on triple module redundancy (TMR) structure.

⑨Woodward:505 series governor 9907-164 And other products

⑩Bosch Rexroth:Indramat,I/O module,PLC CPU,Motors, drives and other products.

◆Motorola:MVME 162、MVME 167、MVME1772、MVME177and other products.