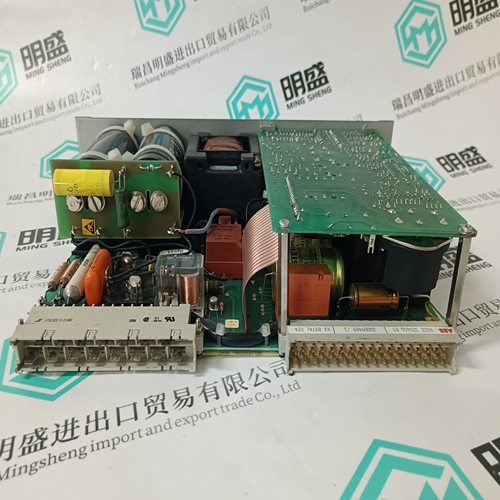

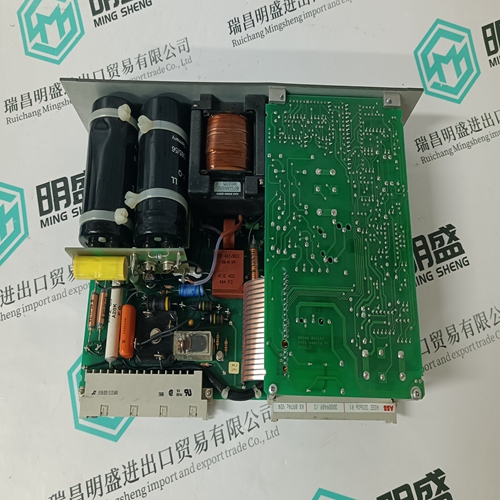

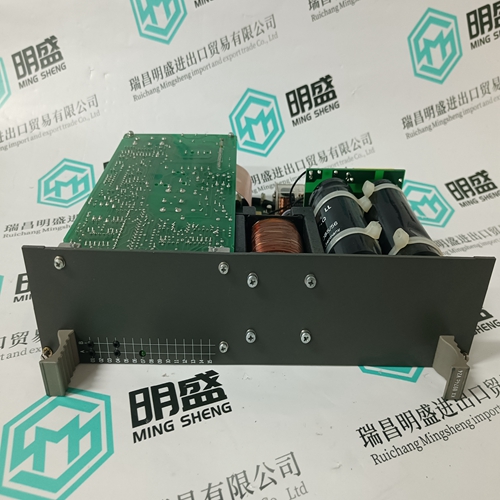

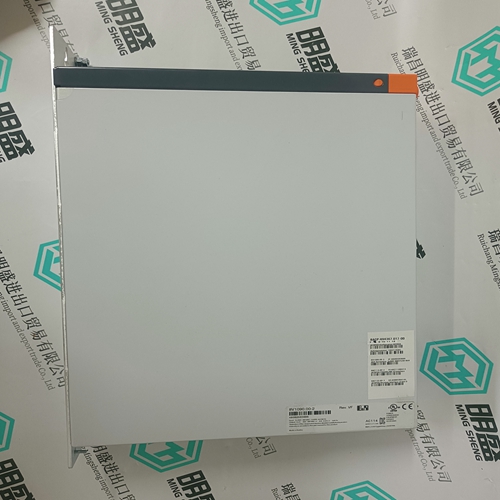

Home > Product > DCS control system > KX8974c V24 HIEE320606R1 Control input module

KX8974c V24 HIEE320606R1 Control input module

- Product ID: KX8974c V24 HIEE320606R1

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:KX8974c V24 HIEE320606R1Control input module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

KX8974c V24 HIEE320606R1 Control input module

Configuration The operation of the HNC100 is based on the creation of application-specific data sets. These data sets are generated on a PC and sent via the serial interface to the HNC100. The combination of the user program and data sets is called “project”. The software configuration follows determined steps: 1. The tasks to be performed by the HNC100 are to be defined and in flowchart. The definition also refers to the meaning of inputs and outputs and the parameters used. 2. The functions of the sequence charts have to be implemented in the form of a sequence of NC commands. 3. The machine data (selection of transducers and controllers) and the parameters of the NC program have to be defined. 4. The data are sent to the HNC100. 5. Settings and program sequences are optimized on the machine. PC program “WIN-PED 5“ The PC program “WIN-PED 5” helps the user perform configuration tasks. It is used for programming, setting and diagnostics of the HNC100. Scope of functions: – Convenient dialog functions for online or offline setting of machine data – NC Editor with integrated syntax check and program compiler – Support for the definition of parameters used in the NC program – Dialog window for online setting of parameter values – Comprehensive options for displaying process data, digital inputs, outputs and flags – Recording and graphical representation of up to four process variables via a selection of trigger options – Dialog for the graphical definition of special functions (determination of function via polygon)

System requirements

– IBM PC or compatible system – Windows 2000 or Windows XP – RAM (recommended: 256 MB) – 60 MB free hard disk space Note for storing R parameters in the HNC100: Damage to the internal memory (EEPROM) due to too high a number of write access! When ticking the „Save in EEPROM“ checkbox (WIN-PED menu: R parameter), you write to the internal memory (EEPROM). As every EEPROM allows only for a limited number of write access before its cells are destroyed, you should make sure that the number of such write access is limited. Information on the scope of supply: The PC program “WIN-PED 5“ is not included in the scope of supply. It can be downloaded free of charge on the Internet! Download on the Internet: www.boschrexroth.de/hnc100 Queries: support.nc-systems@boschrexroth.de Position controller: – PDT1-controller – Linear gain characteristic curve – Direction-dependent gain adjustment – "Inflected" gain characteristic curve – Gain alteration possible via the NC program – Fine positioning – Residual voltage principle – Zero point error compensation – Active damping – Command value feedforward – Limitation of control output via the NC program – “Position-dependent braking“ – Intermediate electronics for use with commercial NC controls – Synchronization control (only in conjunction with VT-HNC100-2…)