Home > Product > DCS control system > ABB INIT03 Digital output module

ABB INIT03 Digital output module

- Product ID: INIT03

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ABBINIT03Digital output module

- Get the latest price:Click to consult

ABB INIT03 Digital output module

LOADING THE ROTISSERIE SKEWER

1Screw the bushing onto the skewer rod at the opposite end from the point.

2. Slide and tighten the counter balance apparatus onto the skewer rod approximately 2 to 4 inches from the bushing.

3. Slide the first meat fork onto the skewer rod prongs toward the food.

4. Center the product to be cooked on the skewer, and then push the meat forks firmly together.

5. Tighten the wing nuts.

6. It may also be necessary to wrap the food with butcher’s string to secure loose portions. Never use nylon or plastic string to wrap the food.

7. Once the food is secure, insert the skewer into the motor.

NOTE

It is normal for the skewer to flex when larger cuts of meat are being cooked. If the meat scrapes on the cooking grids during any part of the rotation, the cooking grids must be removed. Test this clearance before lighting the grill as the cooking grids become hot when the grill is lit. Adjust the counter balance weight to balance the heavier side of the meat and avoid lopsided rotation of the rotisserie motor.

When using the rotisserie burner, remove the warming rack. High heat from the burner may cause the warming rack to bend.

BEFORE LIGHTING

Inspect the gas supply hose prior to turning on the gas. If there is evidence of cuts, wear, or abrasion, it must be replaced prior to use. Refer to “Leak Testing” on page 11. WARNING Do not use the grill if the odor of gas is present. Contact customer service at 1-800-554-5799. Screw the regulator (type QCC1) into the cylinder, and leak check the hose and regulator connections before operating the grill (See the “Leak Testing” instructions on page 11). Only the pressure regulator and hose assembly supplied with the unit should be used. Never substitute regulators. If a replacement is necessary, contact customer service for proper replacement.

Company introduction

Temporal Ming sheng automation equipment co., LTD. Was established in April 02, 2021, registered jiujiang ruichang city in jiangxi province, east yi road no. 23 lake farmers 401 mall, the legal representative person Zhou Zuochen.

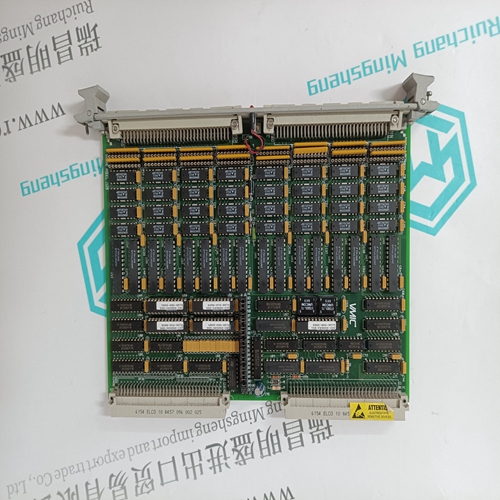

[Main Products]

Main products: PLC and DCS system spare parts modules of world famous brands

①Allen-Bradley 1756、1746、1747、1771、1785

②Schneider 140 Series PLC module

③General electric GE

IC693 IC697 IC698 Series PLC module

DS200 DS3800 DS215 IS200 IS215 IS220 Series gas turbine module

VMIVME Control module of series

④Bently:3500 series cards 3500/22M、3500/15、3500/92 And other products

⑤ICS TRIPLEX

⑥ABB Robots. FANUC Robots、YASKAWA Robots、KUKA Robots、Mitsubishi Robots、OTC Robots、Panasonic Robots、MOTOMAN Robots。

⑦EMERSON:Spare parts for OVATION system, WDPF system and MAX1000 system.

⑧ Invensys Foxboro: I/A Series system, FBM (field input/output module) sequential control, ladder logic control, accident recall processing, digital analog conversion, input/output signal processing, data communication and processing, etc. Invensys Triconex: redundant fault-tolerant control system, Zui modern fault-tolerant controller based on triple module redundancy (TMR) structure.

⑨Woodward:505 series governor 9907-164 And other products

⑩Bosch Rexroth:Indramat,I/O module,PLC CPU,Motors, drives and other products.

◆Motorola:MVME 162、MVME 167、MVME1772、MVME177and other products.