Home > Product > DCS control system > ABB SDCS-I0B-3 Channel isolation module

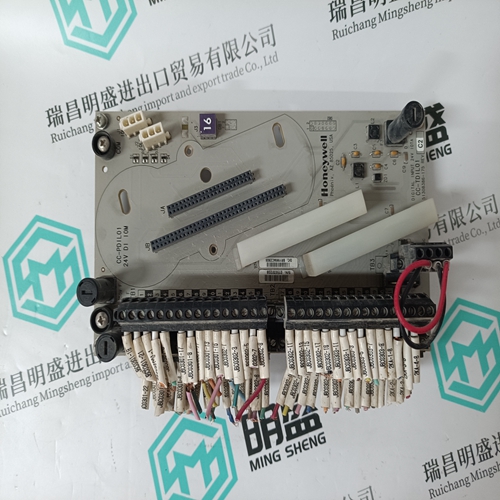

ABB SDCS-I0B-3 Channel isolation module

- Product ID: SDCS-I0B-3

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ABBSDCS-I0B-3Channel isolation module

- Get the latest price:Click to consult

ABB SDCS-I0B-3 Channel isolation module

Keep outdoor cooking gas appliance area clear and free from combustible materials, gasoline and other flammable vapors and liquids. 2.Do not obstructing the flow of combustible and ventilation air. 3.Keep the ventilation openings of the cylinder enclosure free and clear from debris.

Extreme care should be taken when moving a burner. It must be correctly centered on the orifice before any attempt is made to relight the grill. Frequency of cleaning will depend on how often you use the grill WARNING Failure to properly place the burner over the orifice could cause a fire behind and beneath the valve panel, thereby damaging the grill and making it unsafe for operation.

GRILL BURNER REMOVAL/INSTALLATION

The grill burners are factory installed. To remove the main burners for cleaning: 1. Locate the nut at the rear of the burner on the bottom side.

2. Remove the nut and lift the burner out of the fire box. To reinstall the main burners:

3. Insert the burner over the valve assembly (Item# 15 on Page 23).

4. Insert the back of the burner into the hole at the rear of the fire box and reinsert the nut. 5. Make sure orifice spud is inside the burners ventur as shown in below drawings.

GREASE TRAY CLEANING

The grease tray should be emptied, wiped down and washed after each use with a mild detergent and warm water solution. A small amount of sand or cat litter may be placed in the bottom of the grease tray to absorb the grease. Check the grease tray frequently. Do not allow excess grease to accumulate and flow out of the grease tray.Spiders and insects can nest inside the burners of the grill and disrupt gas flow. This very dangerous condition could cause a fire behind the valve panel, thereby damaging the grill and making it unsafe for operation. Inspect the grill at least twice a year.

Company introduction

Temporal Ming sheng automation equipment co., LTD. Was established in April 02, 2021, registered jiujiang ruichang city in jiangxi province, east yi road no. 23 lake farmers 401 mall, the legal representative person Zhou Zuochen.

[Main Products]

Main products: PLC and DCS system spare parts modules of world famous brands

①Allen-Bradley 1756、1746、1747、1771、1785

②Schneider 140 Series PLC module

③General electric GE

IC693 IC697 IC698 Series PLC module

DS200 DS3800 DS215 IS200 IS215 IS220 Series gas turbine module

VMIVME Control module of series

④Bently:3500 series cards 3500/22M、3500/15、3500/92 And other products

⑤ICS TRIPLEX

⑥ABB Robots. FANUC Robots、YASKAWA Robots、KUKA Robots、Mitsubishi Robots、OTC Robots、Panasonic Robots、MOTOMAN Robots。

⑦EMERSON:Spare parts for OVATION system, WDPF system and MAX1000 system.

⑧ Invensys Foxboro: I/A Series system, FBM (field input/output module) sequential control, ladder logic control, accident recall processing, digital analog conversion, input/output signal processing, data communication and processing, etc. Invensys Triconex: redundant fault-tolerant control system, Zui modern fault-tolerant controller based on triple module redundancy (TMR) structure.

⑨Woodward:505 series governor 9907-164 And other products

⑩Bosch Rexroth:Indramat,I/O module,PLC CPU,Motors, drives and other products.

◆Motorola:MVME 162、MVME 167、MVME1772、MVME177and other products.