Home > Product > DCS control system > PPA322B HIEE300016R2 HIEE400235R1 module

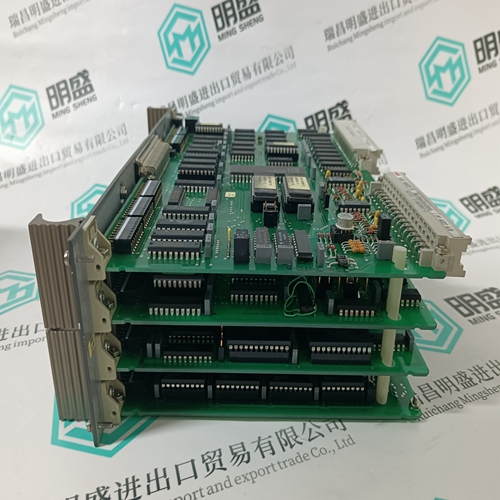

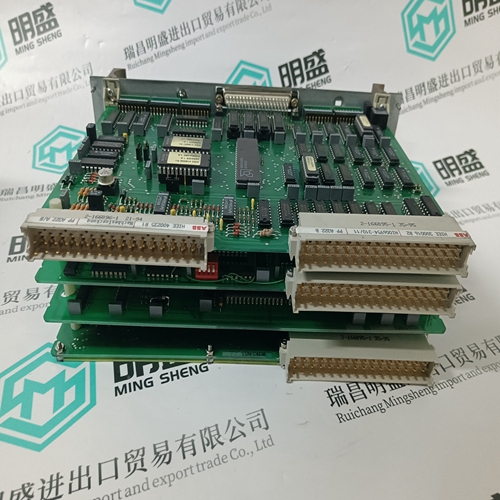

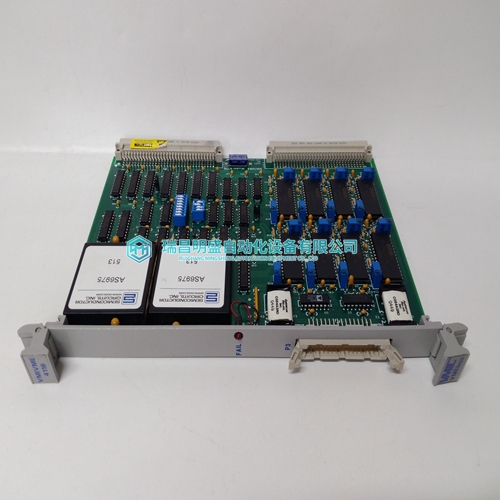

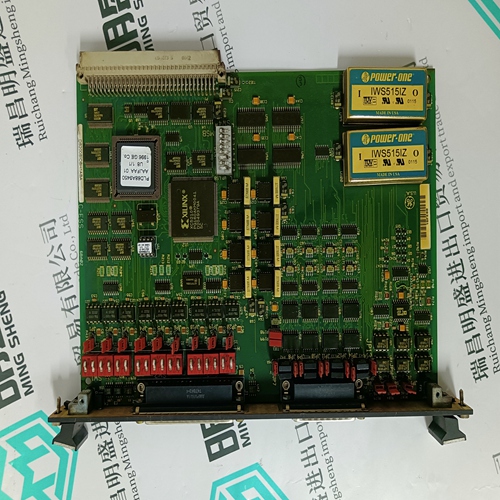

PPA322B HIEE300016R2 HIEE400235R1 module

- Product ID: PPA322B HIEE300016R2 HIEE400235R1

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:PPA322B HIEE300016R2HIEE400235R1module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

PPA322B HIEE300016R2 HIEE400235R1 module

Maintenance notes – The devices are tested in the factory and shipped with default settings. – Only complete devices can be repaired. The repaired components will again be returned with default settings. User-specific settings are not retained. The operator is responsible for reloading the corresponding user parameters and programs.

Powerful hardware for efficient high-speed processing The AC 800PEC combines the floating-point computing performance of the CPU with the flexibility and high speed capability of an FPGA. The system is separated into three performance levels covering different cycle times. Control tasks are allocated depending on their speed requirements: − Very fast tasks down to 25 ns − Fast tasks down to 100 μs − Slow tasks down to 1 ms

The hardware architecture of the AC 800PEC is an ideal match to the three-level software structure. To support the short processing cycle times, the AC 800PEC provides a fast I/O system. Depending on the speed of the I/O connection, it is possible to achieve data throughput times below 100 μs – including the time required to read, transmit, process, transmit and write the signal.

Transparent software structure

The AC 800PEC is the perfect way to unite the system design capabilities of ABB’s ControlIT with the control and simulation capabilities of MATLAB® / Simulink®. Quick implementation of complex control algorithms (e.g. model predictive control) reduces development cycles and costs. Furthermore, the system is open to future technologies. Implementation of the AC 800PEC software on the three performance levels provides an exceptional range of control and communication functionality: Level 1: System engineering (ControlIT) ABB’s ControlIT supports all 5 IEC61131-3 programming languages and uses ABB’s Control Builder as the programming tool. This is the level on which system engineers implement functions that do not require high-speed performance but demand quick and easy adaptation to a specific project.

AC 800PEC controllers can also be fully integrated into ABB’s 800xA automation systems. Level 2: Product & control development (MATLAB / Simulink™) Fast closed-loop control applications are designed using MATLAB® / Simulink®. C-code is automatically generated and downloaded to the embedded device using Real-Time Workshop® from MathWorks®. Typically, it is on this level that control developers will implement the control, the protection, the state machine and other functions. Level 3: Communication & very fast logic (VHDL) Extremely fast processes are programmed in VHDL. Protocols and some control logic requiring extremely short cycle times are implemented on this level. The standardized tasks are available as firmware modules and are not accessible to the application developers.