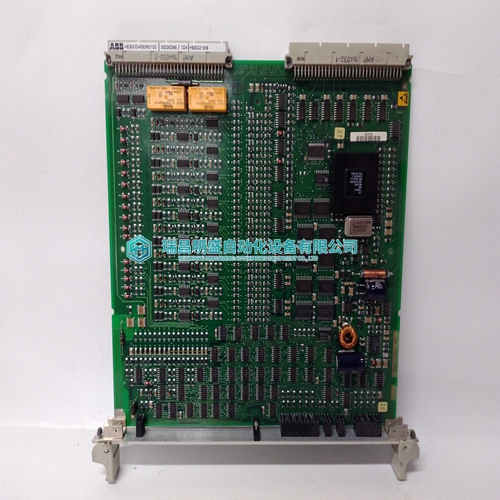

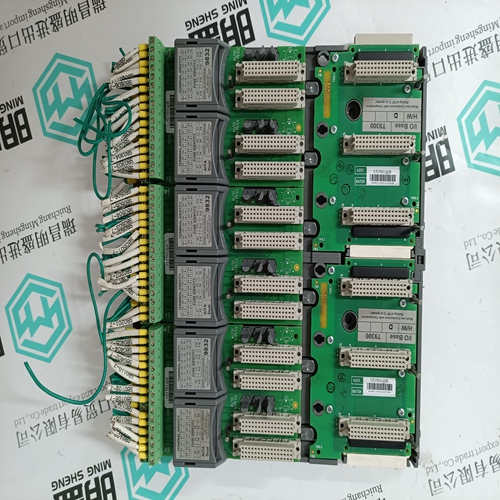

Home > Product > DCS control system > ABB SDCS-PIN-20XB Thermal resistance module

ABB SDCS-PIN-20XB Thermal resistance module

- Product ID: SDCS-PIN-20XB

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ABBSDCS-PIN-20XBThermal resistance module

- Get the latest price:Click to consult

ABB SDCS-PIN-20XB Thermal resistance module

The European Machinery Safety Directive EN 418 requires all emergency OFF devices to be self-latching types and to have positive (direct) opening operation. Devices have to be manually reset. Actuators shall be mushroom head type and colored RED. The background immediately around the device actuator should be colored YELLOW. See Page 47-42 for yellow guard. The new E22 trigger action operators in conjunction with yellow nameplates and DOA (Direct Opening Action) contact blocks are fully compliant with this safety directive. Features ■ Safety interlock against inadvertent operation

■ Stop command and latching occur simultaneously ■ Contacts cannot be “teased” open

■ Direct Opening Action (DOA) contact blocks ■ Resetable by rotation of actuator

Periodic Inspection

Industrial control equipment should be periodically inspected. Eaton recommends inspection of Emergency Stop devices for proper mechanical operation after every 500 hours of elapsed time. See National Electrical Manufacturers Association (NEMA) Standard No. ICS 1.3, Preventive Maintenance of Industrial Control and Systems Equipment, for guidelines in setting up a maintenance program.

Industrial control equipment should be periodically inspected. Eaton recommends inspection of Emergency Stop devices for proper mechanical operation after every 500 hours of elapsed time. See National Electrical Manufacturers Association (NEMA) Standard No. ICS 1.3, Preventive Maintenance of Industrial Control and Systems Equipment, for guidelines in setting up a maintenance program.

Indicating Light Units — Modular

■ Standard and PresTest Types

■ Plastic or Metal Operators

■ Full Voltage LED Light Units or

■ Full Voltage, Resistor or Transformer Incandescent Light Units

■ Plastic Lenses PresTest — This device incorporates a press-to-test feature whereby depressing the lens disconnects the light from the source being monitored and connects the lamp to a continuously energized circuit for immediate test for a faulty lamp.

Company introduction

Temporal Ming sheng automation equipment co., LTD. Was established in April 02, 2021, registered jiujiang ruichang city in jiangxi province, east yi road no. 23 lake farmers 401 mall, the legal representative person Zhou Zuochen.

[Main Products]

Main products: PLC and DCS system spare parts modules of world famous brands

①Allen-Bradley 1756、1746、1747、1771、1785

②Schneider 140 Series PLC module

③General electric GE

IC693 IC697 IC698 Series PLC module

DS200 DS3800 DS215 IS200 IS215 IS220 Series gas turbine module

VMIVME Control module of series

④Bently:3500 series cards 3500/22M、3500/15、3500/92 And other products

⑤ICS TRIPLEX

⑥ABB Robots. FANUC Robots、YASKAWA Robots、KUKA Robots、Mitsubishi Robots、OTC Robots、Panasonic Robots、MOTOMAN Robots。

⑦EMERSON:Spare parts for OVATION system, WDPF system and MAX1000 system.

⑧ Invensys Foxboro: I/A Series system, FBM (field input/output module) sequential control, ladder logic control, accident recall processing, digital analog conversion, input/output signal processing, data communication and processing, etc. Invensys Triconex: redundant fault-tolerant control system, Zui modern fault-tolerant controller based on triple module redundancy (TMR) structure.

⑨Woodward:505 series governor 9907-164 And other products

⑩Bosch Rexroth:Indramat,I/O module,PLC CPU,Motors, drives and other products.

◆Motorola:MVME 162、MVME 167、MVME1772、MVME177and other products.