Home > Product > Robot control system > SC203-100A-002IR-010-01K-05 Signal conditioning

SC203-100A-002IR-010-01K-05 Signal conditioning

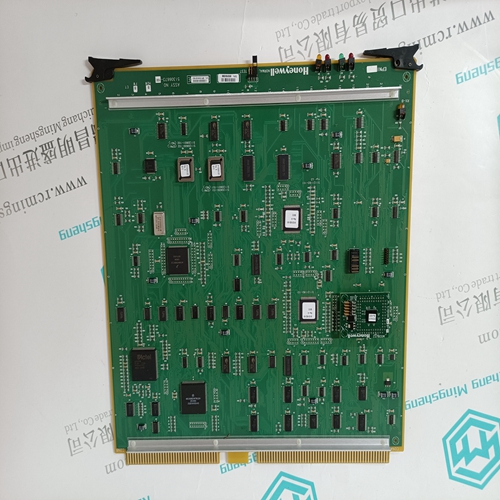

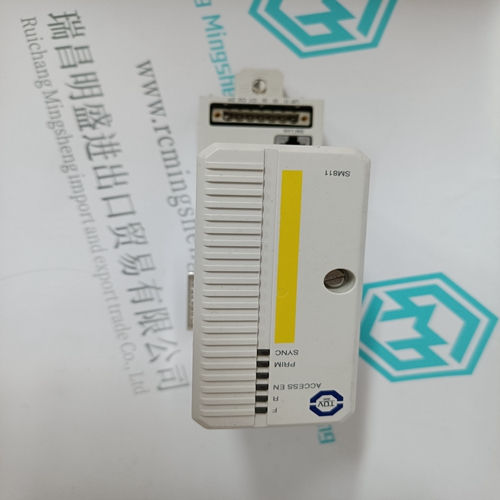

- Product ID: SC203-100A-002IR-010-01K-05

- Brand: CTC

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:SC203-100A-002IR-010-01K-05Signal conditioningCTC

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

SC203-100A-002IR-010-01K-05 Signal conditioning

Main Features ♦ Digital current loop ♦ Velocity loop mode ♦ Available in 3, 6, or 10 amp continuous current ♦ Self protecting power stage ♦ Encoder feedback ♦ PWM switching frequency up to 16 kHz ♦ Supports Danaher Motion Kollmorgen’s wide range of motor solutions ♦ Optional 24 VDC logic input supply, to separate from main supply ♦ Easy tuning and setup using MOTIONLINK for Windows ♦ Easy initialization utilizing a Personality Module. Robust Design ♦ Fully isolated electronics ♦ Fault Protection against output phase to phase short circuit, over-voltage, under-voltage, overcurrent, over-temperature (motor and drive), feedback loss ♦ Current foldback (I2t) provides protection against over-heating drive ♦ Can be optionally used with Danaher Motion Kollmorgen's Regeneration Resistor

♦ Incremental Encoder A/B/Z with HED (Hall Effect Device) ♦ Incremental Encoder A/B with HED (Hall Effect Device) ♦ HED (Hall Effect Device) sine wave or six step ♦ Resolver (only w/ Logic power supplied from external 24 VDC)

MOTIONLINK Software Environment

♦ MOTIONLINK version from 4.3 ♦ Easy setup, commanding, and monitoring techniques ♦ Setup wizard to assist users in fast, easy setup ♦ Contains an extensive database for many of Kollmorgen’s motor series ♦ A Backup screen that provides automatic loading of system parameters ♦ Realtime measuring of many system parameters ♦ Status screen indicating system operation and fault/error checking ♦ Extensive On-line Help file (F1) designed to assist the user in MOTIONLINK’s intuitive nature ♦ A set of limit folders allowing you to manipulate the, velocity, current, and filtering limits from one screen ♦ An Input/Output (I/O) screen for easy manipulation of the I/O, thermostat options, encoder output, and hardware position limits capabilities ♦ A Feedback Device screen that provides realtime pictorial positioning information. It also includes a Resolver Zeroing routine and an encoder initialization screen ♦ A Control Loop screen that provides direct manipulation of velocity loop gain parameters Monitoring and Troubleshooting Tools ♦ Control loop monitoring via terminal o Current/torque (I, IA, IC,ICMD, IMAX, ICONT, DICONT, DIPEAK) o Speed (V, VCMD, VE) ♦ Dual-state digital output (O1, can be used to communicate occurrences of foldback) ♦ Software status switch indicator provided for Configurable Inputs IN ♦ Analog output to monitor Current/Velocity (V,VE,I,ICMD)