Home > Product > DCS control system > DSBB110A 57330001-Y Control card

DSBB110A 57330001-Y Control card

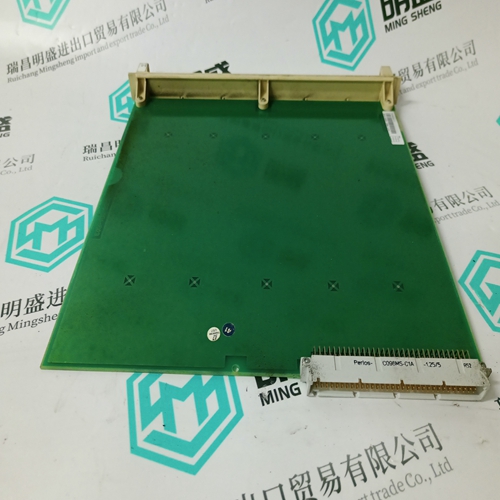

- Product ID: DSBB110A 57330001-Y

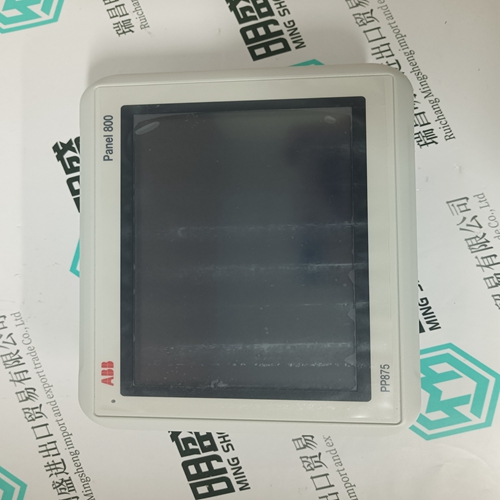

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:DSBB110A 57330001-YControl card

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

DSBB110A 57330001-Y Control card

Restoring Factory Variable Parameters: To restore the original factory variable parameters, pull down the Configure menu, select Motor, and select the motor family and motor model. Click the “To Drive” button to send the variable parameters to RAM and the “RAM/E2 SAVE” button to save to EEPROM. Restoring Custom Variable Parameters: This process assumes that you saved the custom variable parameters to a .SSV file, as described above. To restore the custom parameters, pull down the Edit menu, select Backup Variables, and click on “Open”. Highlight the custom .SSV file to import variable parameters into editor. Click “Xmit” to send variable parameters to drive. Terminal Mode Use the MOTIONLINK Terminal Mode (or any other “dumb” host) to directly monitor or modify the variable set and command the drive. This approach should only be taken when a PC with a Windows operating system is not available and/or you are well-versed with the variable and command set. Each variable and command are referenced for its syntax and parameter definition. The variables and commands are grouped alphabetically for easy look-up and are found at the end of this manual. Be sure you review this information before you begin.

Initial Startup

Most drives are shipped from the factory already configured for a particular motor. You can verify this by applying logic power and monitoring the Status Display. A factory-configured drive goes through a power-up sequence flashing all segments of the display before settling out to a number indicating the mode of operation. If the drive is not configured with a particular motor, the display will flash a minus sign "-", indicating that you must enter drive, motor, and application variable parameters. The remainder of this section describes the process of setting up a non-configured drive. Caution must be taken when applying power to the drive. It is factory-configured to enable upon application of power. Verify that the hardware Remote Enable (REMOTE) enable switch is disabled. Upon powering up, the SERVOSTAR performs a series of self-tests. If the Status Display illuminates a solid number, then no errors were found and the EEPROM has loaded its variable parameters (or loaded with default values in case of invalid EEPROM data) into RAM. The Remote Enable switch on the I/O connector (C3) may now be energized, thus enabling the servo loops.