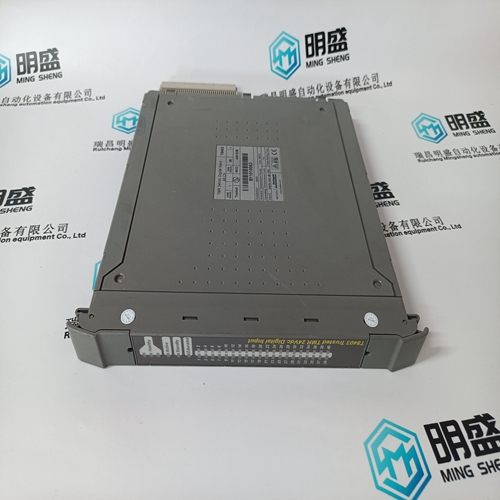

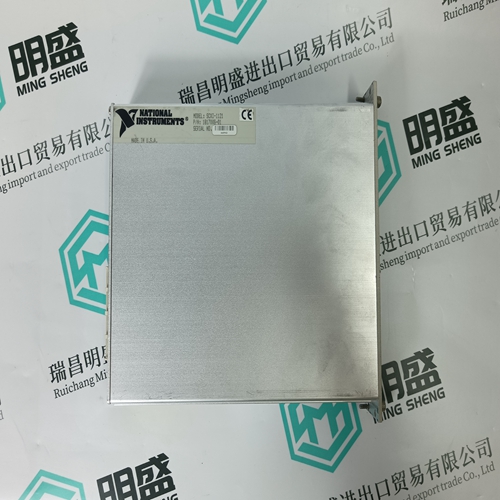

Home > Product > PLC programmable module > ICS TRIPLEX TC-201-02-4M5 Overspeed Tachometer Module

ICS TRIPLEX TC-201-02-4M5 Overspeed Tachometer Module

- Product ID: TC-201-02-4M5

- Brand: ICS TRIPLEX

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ICS TRIPLEXTC-201-02-4M5Overspeed Tachometer Module

- Get the latest price:Click to consult

ICS TRIPLEX TC-201-02-4M5 Overspeed Tachometer Module

This document describes the standard program for roll feed applications selected using the F functions. This makes a quick and secure integration of a Rexroth Indramat system for a functioning roll feed possible (Turnkey solution). For applications with expanded functions, all services are available via the Service menu of the single-axis control ELC for free programming. (See documentation on single-axis control ELC DOK-ECODR3-FLP-01VRS**- FK01-DE-P MN 287131 or DOK-ECODR3-FLP-01VRS**-FK01-DE-P MN 287131). The customer thus has at his disposal all options for a quick and flexible application of the Rexroth-Indramat solution

The Tasks of a Roll Feed

It is the task of a roll feed to transport material (sheet-metal, wiring and so on) under a press, cutter or stamper. The material may only be transported if the stamping or cutting tool is open. The synchronisation between feed and press is controlled with an external signal (feed area) which signals the position of the press.

The Hardware Needed

The Indramat system for a standard roll feed with ELC control is made up of the following hardware components: Drive controller DKC21.3 Servo motor MKD o MHD BTV04 operator terminal The program sequence of a standard roll feed in the ELC control. The feed takes place before the press hub (feed guides) and the press is operated in a single hub.

Quality assurance service

1. We provide high-quality parts of various brands, and you will find full

The model meets your needs.

2. For models that have been out of production for many years, we have all hard to find parts, so we can directly find us to solve all problems for you at one time.

3. If you are in a hurry to use this product, we can dispatch it for you.

4. All products can enjoy a one-year warranty service,

5. Our products are new and unused.

6. If you need a large quantity, you can contact us and I can offer you a discount.

7. You can ask me about the price and more information about the product via email. We welcome you