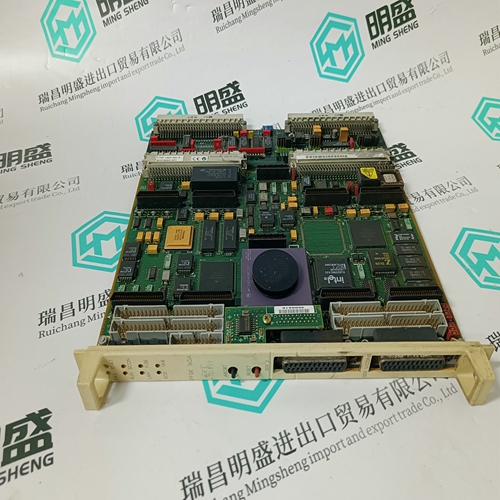

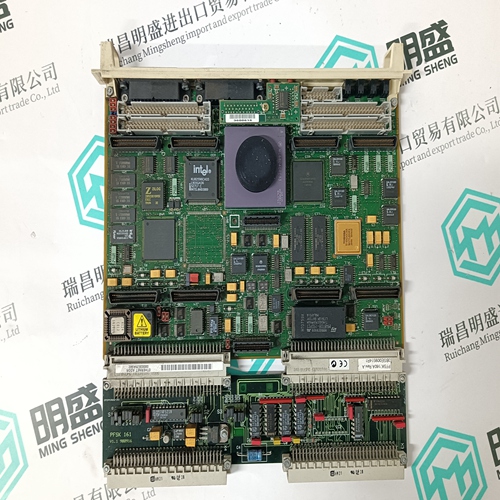

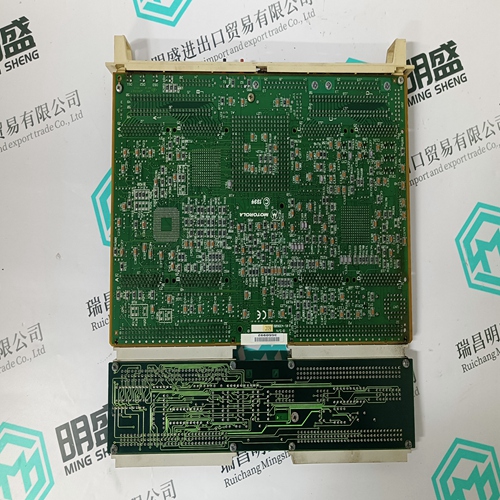

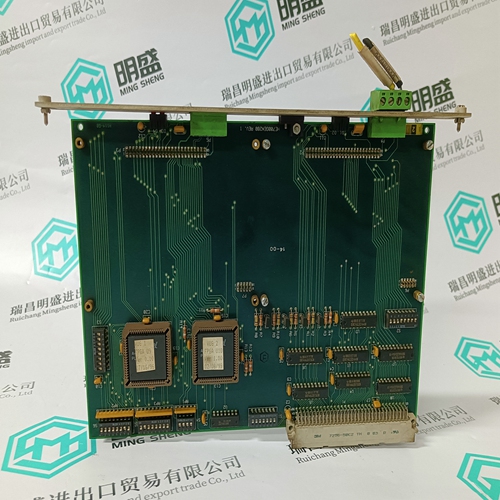

Home > Product > DCS control system > PFSK160A 3BSE009514R1 Contact expansion module

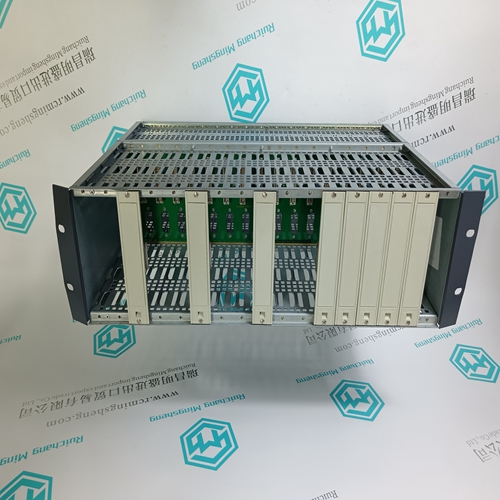

PFSK160A 3BSE009514R1 Contact expansion module

- Product ID: PFSK160A 3BSE009514R1

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:PFSK160A 3BSE009514R1Contact expansion module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

PFSK160A 3BSE009514R1 Contact expansion module

The commissioning wizard -available on the control panel and the PC tool - makes start up of the drive extremely easy, by simply guiding the user through the start up procedure. In addition, the DCS 400 contains application macros. By selecting a macro from a menu, the user can pre-select the software structure and the I/O connection, thus saving time and eliminating any errors. The DCS 400 carries the CE Mark and is designed and produced according to the quality standard ISO 9001.

Drive functions Speed ramp function generator (S-ramp, 2 accel / decel ramps) Speed feedback via tacho, encoder, EMF Speed controlling Torque / current reference processing External torque limitation Current controlling Automatic field weakening Automatic optimization for armature-circuit current, field current, speed controller, EMF regulator, flux adaptation Speed monitor On/Off control logic Remote/local operation Emergency stop Automatic phase sequence detection Motor overload detection Internal motor potentiometer function for the speed reference Jog function Configuration macros

Activation and operator-control

analogue and digital inputs and outputs fieldbusses MMC (man-machine communication) via: Drive Window Light (start-up and maintenance program) PC programs can be run under all commonly used Windows® environments (3.1x, 95,98, NT): Parameter programming Fault detection Feedback display and analysis Fault logger DCS400PAN Removable control and display panel with plain text display for: Guided commissioning Parameter programming Fault detection Reference and feedback display Local operation

Self-test Fault logger Motor monitoring Speed feedback error Overtemperature (PTC evaluation) Overload (I² t) Overspeed Stalled motor Armature-circuit overcurrent Armature-circuit overvoltage Minimum field current Field overcurrent Power converter protection Overtemperature Watchdog function Mains voltage interruption

To match a drive systems components as efficiently as possible to the driven machines load profile, the power converters can be dimensioned by means of the load cycle. Load cycles for driven machines have been defined in the IEC 146 or IEEE specifications, for example.