Home > Product > DCS control system > ABB PXAA 401 3BSE017233R1 CENTRAL UNIT

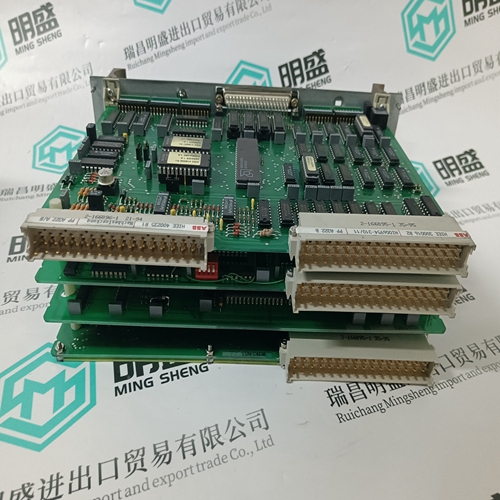

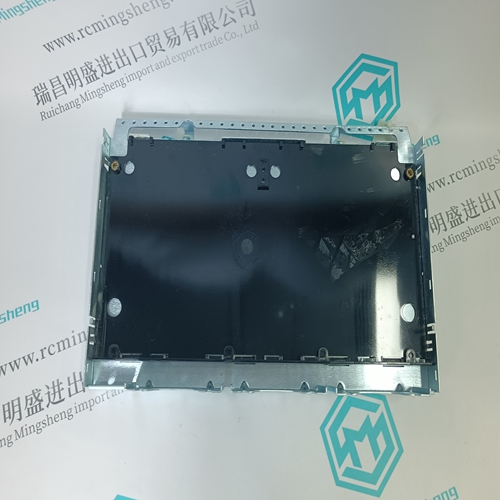

ABB PXAA 401 3BSE017233R1 CENTRAL UNIT

- Product ID: PXAA 401 3BSE017233R1

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ABBPXAA 4013BSE017233R1CENTRAL UNIT

- Get the latest price:Click to consult

ABB PXAA 401 3BSE017233R1 CENTRAL UNIT

• The connecting leads should be suitable for the type of use, as well as the voltages and amperages concerned.

• The protective earth must be connected to the terminal marked PE.

• All cables used should be provided with a shield and in addition, the encoder cable should feature twisted pair leads.

• The power supply is switched off before connecting and disconnecting the power connection and signal connections.

Before commissioning, please check that:

• The actuator is properly mounted,

• All electrical connections and mechanical connections are designed according to requirements,

• The protective earth is properly connected,

• All attachments (brakes, etc) are operational,

• Appropriate measures have been taken to prevent contact with moving and live parts,

• The maximum speed nmax is specified and cannot be exceeded,

• The set up of the drive parameters has been executed, • The commutation is adjusted correctly

Check the direction of rotation of the load uncoupled.

In the event of changes in the normal operating behaviour, such as increased temperature, noise or vibration, switch the actuator off. Determine the cause of the problem and contact the manufacturer if necessary. Even if the actuator is only on test, do not put safety equipment out of operation. This list may not be complete. Other checks may also be necessary Due to heat generation from the actuator itself, tests outside the final mounting position should be limited to 5 minutes of continuous running at a motor speed of less than 1000 rpm. These values should not be exceeded in order to avoid thermal damage to the actuator.

Application industry

The products can be used in the following industries: power plant, paper making, steel, mining, rubber, water supply, cement, chemical industry, glass, printing

Textile, machinery, plastics, coatings, medicine, hospitals, food, hotels, scientific research institutions

This article from the temporal Ming sheng automation equipment co., LTD., reproduced please attach this link: http://www.stockdcs.com/