Home > Product > Servo control system > WOODWARD 5466-253 Input logic module

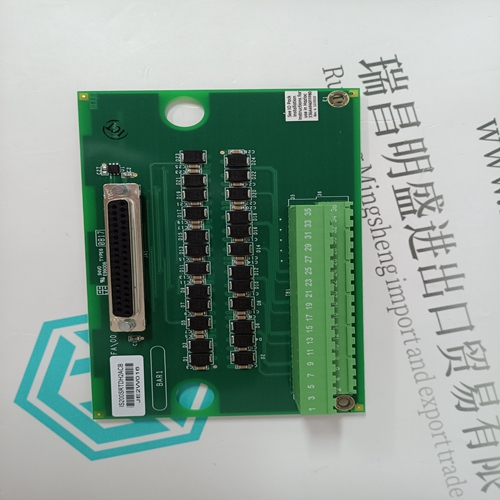

WOODWARD 5466-253 Input logic module

- Product ID: 5466-253

- Brand: WOODWARD

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:WOODWARD5466-253Input logic module

- Get the latest price:Click to consult

WOODWARD 5466-253 Input logic module

These tabs allow the user to configure additional features of

the PC830. During this initial set up the default values on

each of these tabs will be used.

Brand display

ABB、GE/FUANC、FOXBORO、TRICONEX 、BENTLY、A-B、EMERSON 、MOTOROLA、XYVOM、HONEYWELL 、REXROTH、KUKA、NI、DEIF、Yokogawa、WOODWARD、Reliance Electric、SCHNEIDER 、MOOG、PROSOFT、KOLLMORGEN、ICS TRIPLEX、HIMA

This article from the temporal Ming sheng automation equipment co., LTD., reproduced please attach this link: http://www.stockdcs.com/