Home > Product > Servo control system > Woodward 5466-1000 Speed module

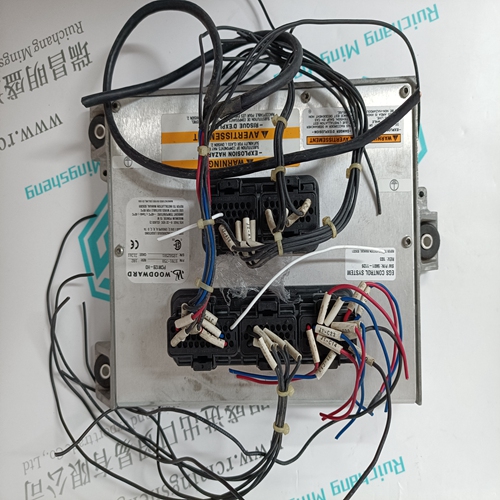

Woodward 5466-1000 Speed module

- Product ID: 5466-1000

- Brand: WOODWARD

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:Woodward5466-1000Speed module

- Get the latest price:Click to consult

Woodward 5466-1000 Speed module

An encoder with a 1024 line count is mounted to a continuous web embosser machine. A PC830 is setup as a position follower such that for every 1 rev of the encoder the PC830 commands the follower motor to move 1 rev (ratio of 1:1 in encoder revs to motor revs). The drive will be required to phase advance the follower motor ¼ rev when an input from a PLC occurs. Likewise, the drive will also be required to decrement the follower motor (phase retard) by ¼ rev when another input occurs. These phase advance/retard moves will allow the servo to emboss the imprints into the web ahead or behind where they typically would be without any phase adjustment.

First calculate the required gearing ratio

between the master encoder and the slave motor. A 1024 line count encoder will output 4096 quadrature counts per encoder revolution.The phase advance and phase retard index move distances must also be calculated. The motor must perform an index move of ¼ rev (65536/4 = 16384 counts). Therefore, program two preset incremental moves of Distance =16384 counts and –16384 counts. Phase correction moves are commanded on top of gearing. To prevent backward motion of the follower, ensure that RunSpeed < DigitalCmdFreq

It may be necessary to refine the tuning

of the system in order to reduce the steady state position following error (position lag). Steady state position following error can be minimized by increasing the velocity feedforward gain (Kvff). Setting Kvff to 100% will reduce this error to zero, however at the expense of potential excessive overshoot. Therefore, your system may require that Kvff be set to a value less than 100% (typically around 70-80%). For additional information on tuning refer to Chapter 4 (Servo Loop Tuning).

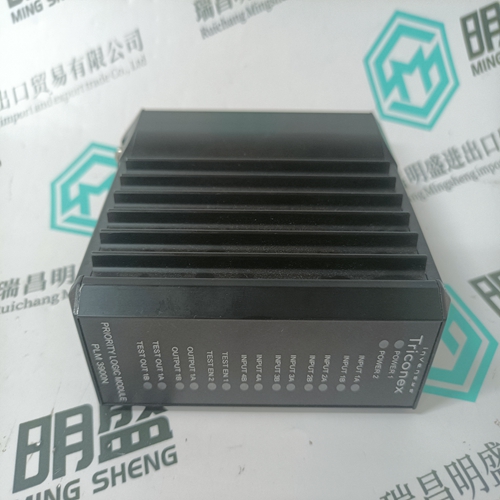

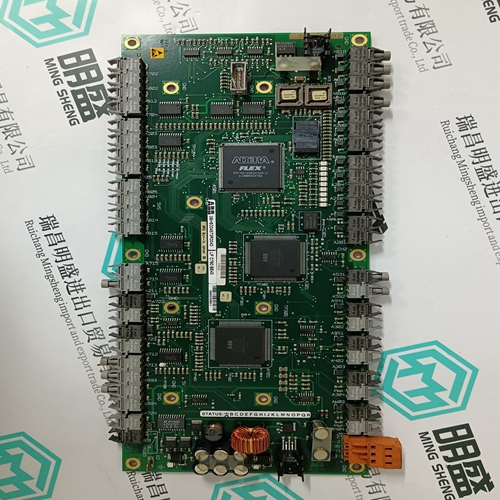

Brand display

ABB、GE/FUANC、FOXBORO、TRICONEX 、BENTLY、A-B、EMERSON 、MOTOROLA、XYVOM、HONEYWELL 、REXROTH、KUKA、NI、DEIF、Yokogawa、WOODWARD、Reliance Electric、SCHNEIDER 、MOOG、PROSOFT、KOLLMORGEN、ICS TRIPLEX、HIMA

This article from the temporal Ming sheng automation equipment co., LTD., reproduced please attach this link: http://www.stockdcs.com/