Home > Product > DCS control system > ABB CMA123 3DDE300403 Channel relay module

ABB CMA123 3DDE300403 Channel relay module

- Product ID: CMA123 3DDE300403

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ABBCMA1233DDE300403Channel relay module

- Get the latest price:Click to consult

ABB CMA123 3DDE300403 Channel relay module

1 Create a New Configuration and select Position Mode – Electronic Gearing as the mode of operation. 2. Set desired number of commanded motor Pulses Out per the number of encoder Pulses In. 3. Click on the Digital I/O tab. Select Gearing On as the function for the input to initiate gearing. 4. Select Start Move as the function on the input used to initiate a preset incremental move. 5. Click on the Predefined Moves tab. Define an Incremental move for the phase advance index move. 6. Create a second incremental move for the phase retard index move.

Registration Moves

Registration marks can be used to perform preset registration moves based upon activation of a registration input. Typically, these moves can be used to advance a product a predefined distance after activation of a proximity sensor input. All registration inputs must be tied to a dedicated registration input on either Input 4 (J2-34) or Input 5 (J2-35).

A conveyor processing material

is being driven by a one inch diameter roller (directly coupled to a motor) incrementing at a constant speed of 1000 rpm. There are marks on the material spaced evenly every eight inches on the conveyor. These marks are detected by a proximity sensor interfaced into Input 4 on the PC830 as a registration input. Once the sensor is activated, the motor advances the conveyor one more inch before coming to a complete stop within 75 milliseconds. After the motor has come to a complete stop, the drive activates an output signaling a nearby PLC that the registration move is complete. The PLC initiates the cycle to repeat itself.

Brand display

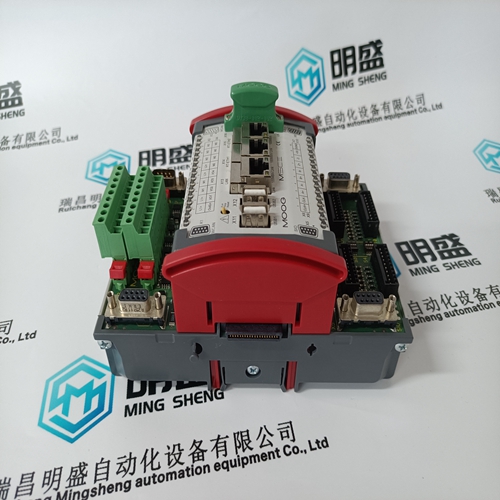

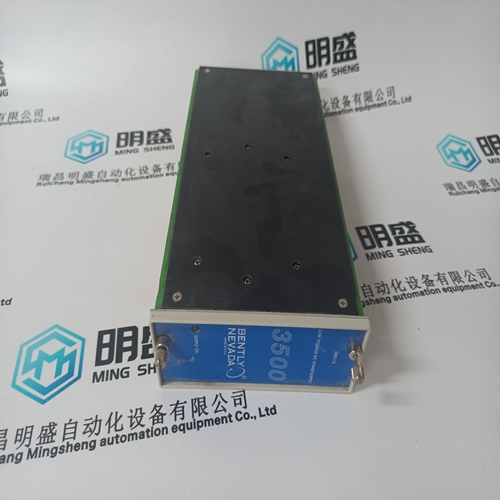

ABB、GE/FUANC、FOXBORO、TRICONEX 、BENTLY、A-B、EMERSON 、MOTOROLA、XYVOM、HONEYWELL 、REXROTH、KUKA、NI、DEIF、Yokogawa、WOODWARD、Reliance Electric、SCHNEIDER 、MOOG、PROSOFT、KOLLMORGEN、ICS TRIPLEX、HIMA

This article from the temporal Ming sheng automation equipment co., LTD., reproduced please attach this link: http://www.stockdcs.com/