Home > Product > DCS control system > ABB 064844-005 Pulse input module

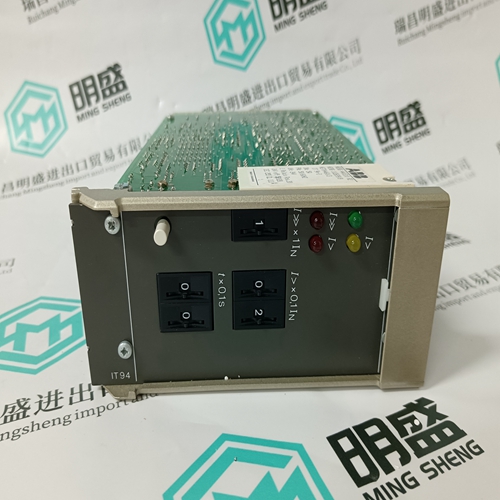

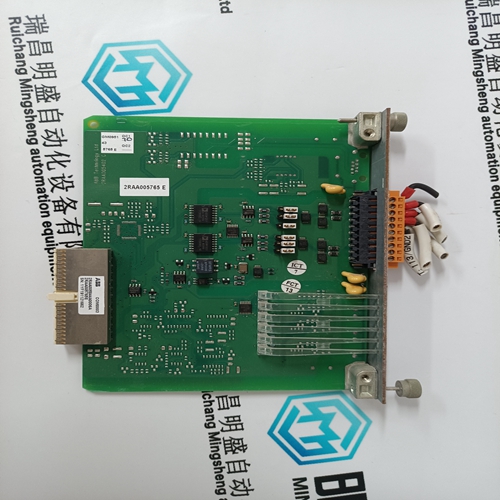

ABB 064844-005 Pulse input module

- Product ID: 064844-005

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ABB064844-005Pulse input module

- Get the latest price:Click to consult

ABB 064844-005 Pulse input module

From the formula for bandwidth, it is seen that bandwidth changes inversely with total inertia. If the load inertia equals the motor plus resolver inertia, the velocity loop bandwidth will be half the values shown. If the load inertia is ten times the motor plus resolver inertia, the bandwidths will be one eleventh these values. Clearly KVP must be increased to compensate for increased load inertia if bandwidth is to be maintained. Typically, load inertia up to 3(motor + resolver) give acceptable performance without further optimization. The most common servo setup problem is adding large load inertia without a corresponding increase in KVP.

Example calculation

1 Motor plus resolver inertia (0.00039 lb-in-sec2 ) for the PMA22 motor can be found in the catalog or 830 Tools’ motor data screen. 2 KT can be found in the catalog as KT RMS (4.31 lb-in/amp) or by using the Back EMF Constant, KE (31.2 Volts/kRPM) shown on 830 Tools’ motor data screen in the following formula: KT RMS = KE RMS*106 3 . (volts/krpm).830 Tools can also be used to make the calculation. Simply enter the total inertia in place of the motor plus resolver inertia when using the Create New Configuration or Edit Existing Configuration buttons and 830 Tools will calculate the appropriate value for KVP to achieve 75 Hz bandwidth.

There is no specific answer to the general question

“What should the bandwidth be?” In general, the higher the velocity loop bandwidth, the faster the settling time will be and the better the rejection of torque disturbances (increased stiffness). Typically, velocity loop bandwidths range from 30 to 100 Hz. However, too high a bandwidth can lower the damping of resonance in mechanical linkages, causing excessive ringing and/or wear in coupled mechanics. Remember, it is the resulting motion at the end of any mechanical linkages that typically matters, not the response at the motor shaft.

Brand display

ABB、GE/FUANC、FOXBORO、TRICONEX 、BENTLY、A-B、EMERSON 、MOTOROLA、XYVOM、HONEYWELL 、REXROTH、KUKA、NI、DEIF、Yokogawa、WOODWARD、Reliance Electric、SCHNEIDER 、MOOG、PROSOFT、KOLLMORGEN、ICS TRIPLEX、HIMA

This article from the temporal Ming sheng automation equipment co., LTD., reproduced please attach this link: http://www.stockdcs.com/