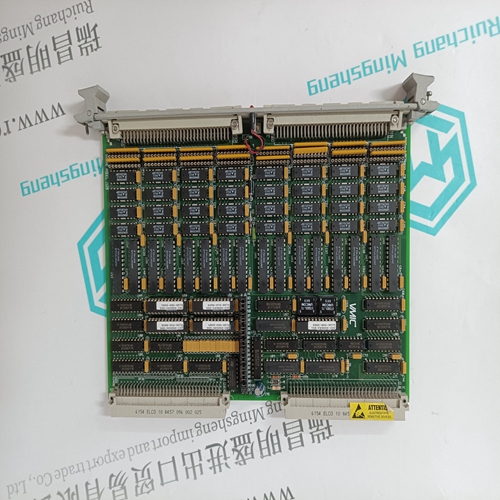

Home > Product > DCS control system > ABB 3BHB038130R4004 Channel input module

ABB 3BHB038130R4004 Channel input module

- Product ID: 3BHB038130R4004

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ABB3BHB038130R4004Channel input module

- Get the latest price:Click to consult

ABB 3BHB038130R4004 Channel input module

To wire-up a comcoder (hall/encoder) for primary feedback on the PC830 perform the following: 1. Connect the comcoder as shown in the diagram below:2. Click on the Edit Drive Configuration Online button and select the variable HallState.If HallState does not sequence in this manner, then swap any two hall sensor phases and repeat step 3.Click on the Create New Configuration button. Select the proper motor, drive, and desired mode of operation. Click on Next.

When the hardware enable is asserted

the motor will initially use the hall signals for commutation. After the first hall state transition occurs, the drive will adjust the commutation angle and start commutation off the encoder. To ensure the adjusted commutation angle is within 5 electrical degrees of the correct angle, the PC830 limits the maximum velocity and maximum acceleration rate the motor can rotate at until this transition occurs as the motor is still not properly aligned during this period. For additional information on the Comcoder (Hall/Encoder) alignment process, contact Pacific Scientific Application Engineering for assistance.

Appendix G Simple ASCII Protocol

The PC830 supports a simple ASCII protocol for serial communications with devices like PLCs or other electronics capable of handling ASCII strings. The simple ASCII protocol command formats are given below. The notation is as follows: { } indicates optional field. <> indicates one character. [ ] indicates a string of characters. Each character is sent using its ASCII representation.

Professional seller

Professional sales of major electrical brand products in the world

Overseas direct purchase of products, authentic inventory, price concessions

After sales warranty, complete models, same products, different prices and services

This article from the temporal Ming sheng automation equipment co., LTD., reproduced please attach this link: http://www.stockdcs.com/