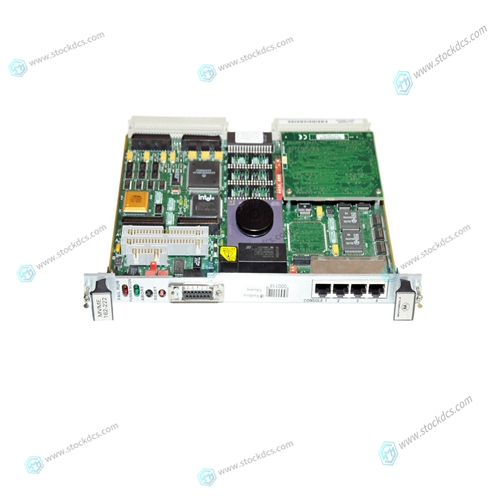

Home > Product > PLC programmable module > MOTOROLA MVME162-222 Dynamic pressure monitor

MOTOROLA MVME162-222 Dynamic pressure monitor

- Product ID: MVME162-222

- Brand: MOTOROLA

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:MOTOROLAMVME162-222Dynamic pressure monitor

- Get the latest price:Click to consult

MOTOROLA MVME162-222 Dynamic pressure monitor

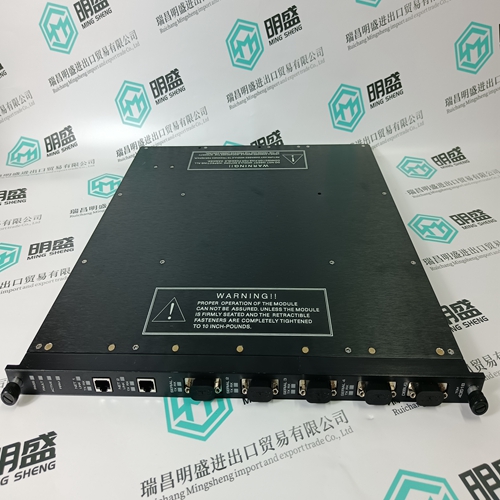

The sampling of oil mist levels takes place via a single pipe sampling system, indicating the exact crankcase compartment in which the high oil mist levels are critical. The air mixture from throughout the crankcase passes through the measuring head‘s housing. If the opacity of the mixture of air from the crankcase exceeds 10% of the alarm threshold that has been set, a damage check starts. The valves in the valve box are switched over according to a proprietary algorithm during the damage check, until the crankcase compartment with the overheating damage has been found. The alarm threshold can be set to 4 levels.

visatron® VN115/87plusEX

• Suitable for the monitoring of 4-stroke Diesel, Gas- and Dual Fuel engines inline or V-type engine arrangements

• ATEX-certified for crankcase environment according to II (2G) [Ex op is II B T 4 G b]

• In the event of dangerous oil mist generation, there is an alarm signal via the alarm relay for high oil mist. There is no indication of the oil mist source location.

The detection of damage takes place

through a header pipe sampling system without localisation of the point of damage. The mixture of atmosphere from the crankcase passes from all individual compartments via the header pipe through the detector‘s pipe connector box into the opacity measurement path in the housing of the measuring head. The alarm threshold can be set to 4 levels.

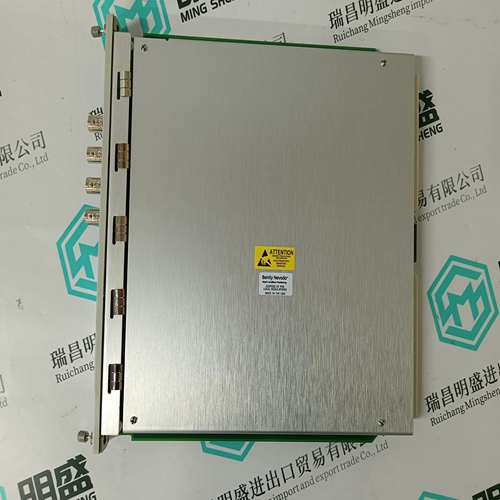

Professional seller

Professional sales of major electrical brand products in the world

Overseas direct purchase of products, authentic inventory, price concessions

After sales warranty, complete models, same products, different prices and services

This article from the temporal Ming sheng automation equipment co., LTD., reproduced please attach this link: http://www.stockdcs.com/