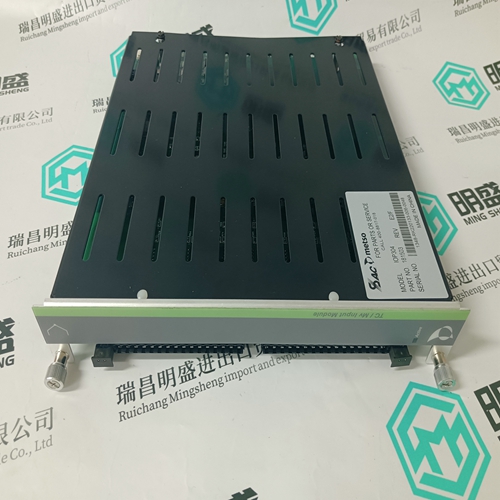

Home > Product > Robot control system > SCHENCK VEG20400 weighing controller

SCHENCK VEG20400 weighing controller

- Product ID: VEG20400

- Brand: SCHENCK

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:SCHENCKVEG20400weighing controller

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

SCHENCK VEG20400 weighing controller

The analog input modules are TÜV certified as noninterfering and when properly configured are also certified for Risk Class 5 safety critical inputs. Safety critical configurations include midvalue selection methods. In safety critical input applications using a single sensor, it is important that the sensor failure modes be predictable and well understood, so there is little probability of a failed sensor not responding to a critical process condition. In such a configuration, it is important that the sensor be tested regularly, either by dynamic process conditions that are verified in the Regent, or by manual intervention testing. Redundant sensors can be used with redundant input modules to eliminate any single points of failure and extend fault tolerance to include the sensors. For additional safety considerations, please refer to the Safety Considerations section of the Regent User’s Guide.

Critical software processes are often placed onto stand-alone workstations, with redundancy provided through replicating that configuration. This permits continued plant operation during maintenance as well as in the unusual event of a workstation failure. Workstations can be remotely mounted in secure enclosures and/or spaces with the operator interface equipment installed through the use of Remote Graphics Units.

OVERVIEW

The Model H92 workstation can be used with Foxboro Evo™ Control Core Services software and Foxboro Evo Control Software, and can also provide a platform for Foxboro®, third-party, and user-written applications. As a multipurpose workstation running the Windows 7 64-bit operating system, the H92 workstation supports execution of system applications, data communications for a broad range of applications, file serving capabilities, and display of graphics and text. It also interfaces with corporate networks at a local or worldwide level. The workstation supports a mouse or optional trackball, an alphanumeric keyboard, up to four USB annunciator or annunciator/numeric keyboards, and one to four monitors. The H92 workstation also supports an optional USB touchscreen (purchased separately with the monitor) and an optional USB speaker set (purchased separately).

The workstation features up to three internal serial ATA hard disk drives, which may be optionally configured as RAID1, and comes with 4 GB of ECC RAM memory (expandable to 16 GB). The processor supports an internal DVD+RW drive. Client/server communication is accomplished using the TCP/IP networking protocol with the integrated Ethernet network port or optional Ethernet network interface cards (NICs). As indicated by the CE logo, the Model H92 workstation conforms to the applicable European Union directives.