Home > Product > PLC programmable module > BENTLY 3500/20 125744-02 Channel module

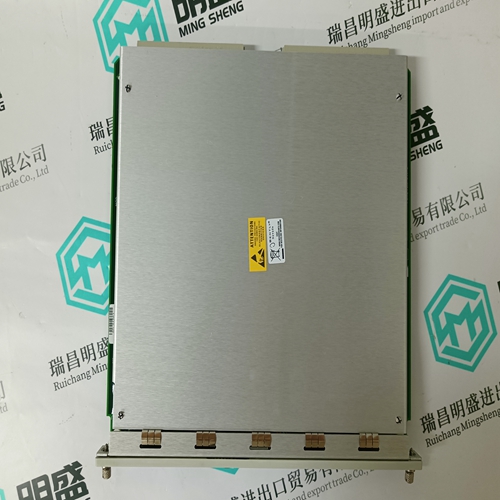

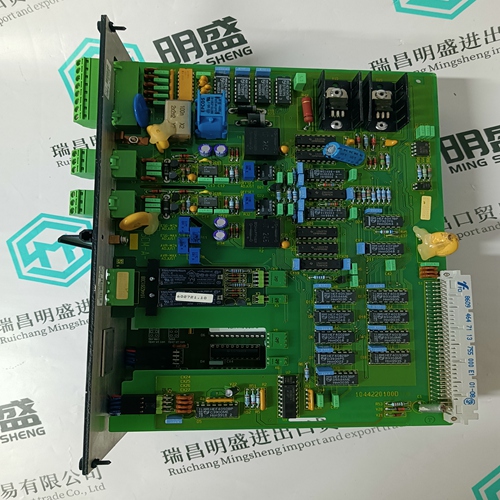

BENTLY 3500/20 125744-02 Channel module

- Product ID: 3500/20 125744-02

- Brand: BENTLY

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:BENTLY3500/20 125744-02Channel module

- Get the latest price:Click to consult

BENTLY 3500/20 125744-02 Channel module

Bently Nevada 3500/20 is a high-performance vibration monitor mainly used to monitor the vibration and status of rotating machinery, in order to detect the operation of the machine in real-time and detect faults in a timely manner.

125744-02 is a configuration option for Bently Nevada 3500/20, with specific configuration instructions as follows:

125744-02 contains two channels

Each channel has 4 input signals for measuring machine vibration, speed, and displacement

This configuration option also includes two digital input channels and one digital output channel

The main functions and functions of Bently Nevada 3500/20 include:

Detect the vibration and status of rotating machinery, monitor the operation of the machine in real-time, and promptly detect faults

Provide various monitoring and diagnostic functions, including vibration monitoring, mechanical condition monitoring, bearing wear monitoring, etc

Supports multiple communication protocols and can be integrated with other monitoring devices to achieve comprehensive machine monitoring and management

Provide real-time data collection and analysis, which can generate detailed monitoring reports and trend analysis, helping operation and maintenance personnel make more accurate maintenance decisions

Bently Nevada 3500/20 is suitable for a wide range of applications, including monitoring and maintenance of rotating machinery in industries such as oil and gas, chemical, power, and manufacturing. It can help enterprises improve equipment reliability and operational efficiency, reduce maintenance costs and risks.

Related products:

BENTLY 3500/20-01 Channel monitoring module