Home > Product > PLC programmable module > MOTOROLA MVME172P-644L interface module

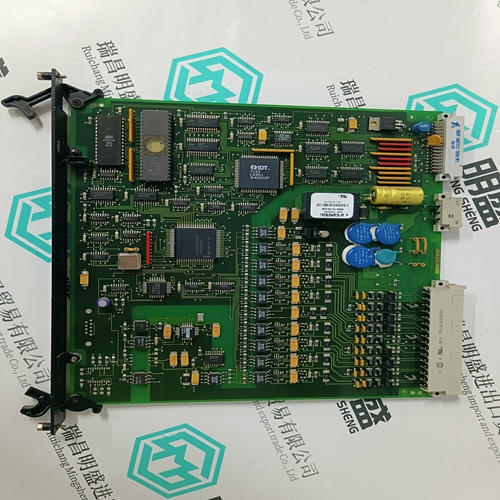

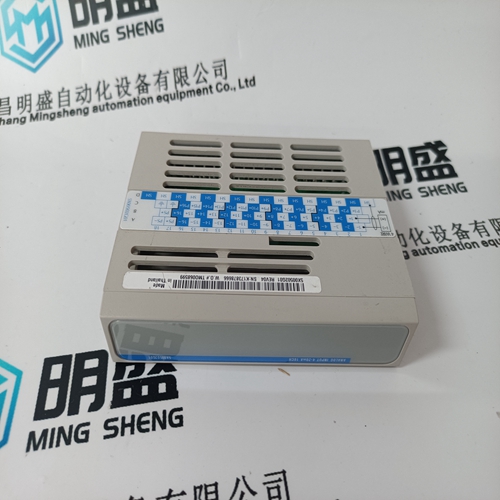

MOTOROLA MVME172P-644L interface module

- Product ID: MVME172P-644L

- Brand: MOTOROLA

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:MOTOROLAMVME172P-644Linterface module

- Get the latest price:Click to consult

MOTOROLA MVME172P-644L interface module

Holding Brake Option. To fix servo axes in a voltage-less state of the machine. The brake works with the „Electrically released“ principle. If no voltage is applied, then a magnetic force fixed the brake disc. This closes the brake and holds the axis. If 24 VDC are applied then the continuous magnetic field is compensated by the electrically-generated magnetic field and the brake opens. The drive controller controls the brake. This ensures the correct on and off sequence in all operating states.

Premature wear of holding brake is possible!

• The brake wears down after about 20,000 revolutions of the motor in a closed state. Therefore, do not use the holding brake as if it were a normal brake to stop a moving axis. This is only permitted in an emergency stop situation. Holding torque must be checked prior to start up. Note: If motors have been stored for extended periods, then the transferrable torque of the holding brake must be checked before the motor is used. If the holding torque specified in the data sheets is not reached, then the brake must be re-finished.

Superior products

-ABB Accuray

--ABB Advant OCS

--ABB Advant-800xA

--ABB H&B Contrans T

--ABB H&B Freelance 2000

--Allen Bradley PLC

--GE Ran card machine accessories,PLC

--ICS Triplex Rockwell T8151B/T8461/T8310

--Triconex/Foxboro:3625/3721/3503E/FBM237/FBM242

--Emerson:CE3008/VE3008/SE3008/A6120/A6312

--Motorola:MCP750/MVME162/MVME2604/MVME5100

--Woodward:9907-164/9907-167/9905-144/9905-018

The company is mainly engaged in above brands. You are welcome to inquire from me via email!

This article from the temporal Ming sheng automation equipment co., LTD., reproduced please attach this link: http://www.stockdcs.com/