Home > Product > PLC programmable module > MOTOROLA MVME2604-1161B Vibration module

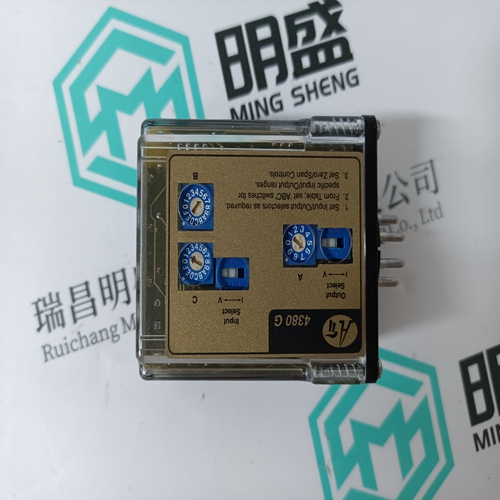

MOTOROLA MVME2604-1161B Vibration module

- Product ID: MVME2604-1161B

- Brand: MOTOROLA

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:MOTOROLAMVME2604-1161BVibration module

- Get the latest price:Click to consult

MOTOROLA MVME2604-1161B Vibration module

Due to the intrinsic limitations of metals as well as sky rocketing costs, many design engineers utilize thermoset composites as a metal replacement material for high-performance applications. Thermoset composites provide more strength, dimensional stability, and corrosion resistance than metals, while increasing design flexibility and manufacturing efficiency. In addition, thermoset composites, such as sheet moulding compound (SMC), offer the following benefits over traditional metals;

Thermal resistance

All thermoset polymers are known for their excellent thermal resistance. Using specific resin systems thermal resistances up to 300°C can be achieved. From technical view these materials are superior to engineering thermoplastics and especially the more economic alternative solution in comparison to high performance thermoplastics. The combination of cross linked polymer and high inorganic filler content by maintaining the excellent moulding characteristics make SMC materials the first choice for applications where elevated service temperatures are required or high temperatures can occur temporarily. For demanding engineering applications it is also crucial that the Coefficient of Thermal Expansion is close to metals and ensure excellent performances in all temperatures.

Superior products

Main products include DCS control system spare parts, PLC system spare parts and robot system spare parts,Advantage brands: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, B&R, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft and other imported industrial parts

This article from the temporal Ming sheng automation equipment co., LTD., reproduced please attach this link: http://www.stockdcs.com/